Engineering requires creativity and smart solutions

engineering (3) working at (3)

Timo Totté (39) and Connie van den Broek (51) both work in the engineering department. Timo is a manager and Connie is a mechanical engineer. The department is expanding in line with Mennens Cleanroom Cranes growth. In other words, new colleagues are more than welcome. Timo and Connie talk about their experience.

Connie joined the team of engineers in 2019. There, she designs cleanroom cranes. She says: “Before that, I worked as a structural engineer through a secondment company. Then I came across Mennens Cleanroom Cranes. They made a good first impression. It seemed like a very interesting company; overhead cranes were new to me. And they offered me the prospect of permanent employment. It was an easy choice to make.”

Converting customer requests into 3D models

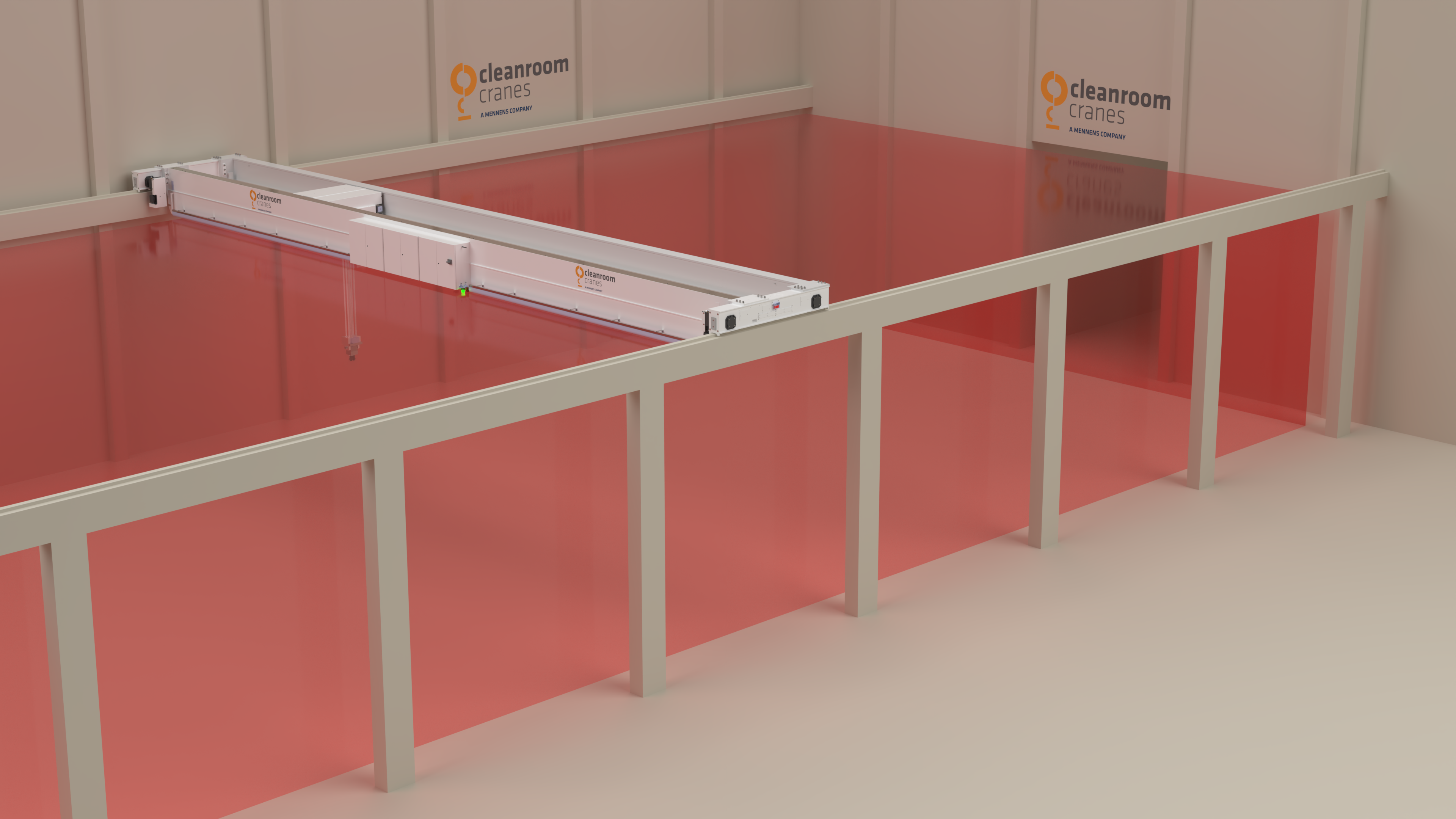

Connie’s focus is on drawing 3D models for the NXE and EXE cranes in the SolidWorks design programme. She continues: “These are our largest and most sophisticated cranes. I convert the client’s requirements and preferences into a 3D model. I take the various points into account, such as the required span, hoisting height and any optional extras, such as shut-off protection and the type of main cabinet. If necessary, I consult with the client, which are often companies abroad. I also provide the drawings for the mechanics in our workshop and the drawings for the customer. Then I draw up the parts list so that our work planner can order the parts.”

Spotting opportunities

Timo joined the team in March 2022. As a manager, he supervises the engineers, analyses how processes can be made even smarter, and implements improvements. Timo says: “When I started, the department consisted of seven engineers. Now there are 14 of us, and this number keeps growing. A larger team requires a different structure and working principles.”

Product owners

Timo gives an example: “We have several different cranes, each of which has its own special features and specifications. In the past, every engineer used to work on every different solution. But it’s impossible to know everything about every single product. So, we’ve made several engineers product owners. They know everything there is to know about a specific lifting solution. If a customer or colleague has a question about that solution, the product owner is the point of contact.”

“We always look for a solution”

Finding creative solutions

There is a lot involved in engineering, Connie explains. “Everything in the drawing has to be exactly right, down to the millimetre. In this process, cranes are often placed into existing spaces. So this requires some creativity. Like the other day, when I got the floor plan for a new cleanroom for one of our customers. The overhead crane that was to be installed there had three control cabinets to control the trolleys, etc. In the defined layout, these would have been placed up against a concrete pillar. I saw a solution in reversing the wheel arches, but then it turned out that the energy supply for the cleanroom was on the other side of the cleanroom. After a lot of reworking, we finally found a solution. This is what makes my work so challenging.”

Torsional stiffness

That’s also a familiar concept for Timo. “Our cranes have standard spans of 10 to 17 metres. Sometimes the customer asks for a smaller structure. That affects the torsional stiffness of the crane. The force density increases and because the structure is so stiff, its own weight prevents it from keeping the wheels on the runway. This causes a kind of slip. When we ran into this issue, we looked for a solution as a team for adjusting the torsional stiffness of the crane. That’s part of the engineering process, too.”

Great working atmosphere

The engineering team consists of a system architect, lead engineers and mechanical engineers. Connie: “There’s a collegial atmosphere. If I ask a question, three or four answers will come back in a flash. We talk with each other and are open to each other’s ideas.” Timo agrees. “We’re growing, but the atmosphere is still like a family business. Personal and informal.”

Proud

And what’s the very best thing about working as a mechanical engineer at Mennens Cleanroom Cranes? Connie concludes: “That I’m working on a special technical product. The cranes I drew in SolidWorks a few months back are now being used to lift the most expensive machines for chip production. That makes me proud.”

Will you be joining us as a new colleague?

Do Connie and Timo’s experiences appeal to you? Explore our vacancies and apply with us.

We would love to meet you.

Interested in more experiences from our team?

Read the interview "From the workshop to the office, we work together here" with Dominique from Administration and Eldrichd from Production.

Or you can read the interview A quick introduction to all the aspects of engineering with Yannick and Danny.

.jpg?width=414&height=414&name=Contact%20image%20414x414%20(1).jpg)