Meet

Mennens Cleanroom Cranes

Leading in clean lifting solutions for over 25 years

In numerous controlled environments worldwide, work is being done smarter and more efficiently thanks to the lifting solutions from Mennens Cleanroom Cranes. Since 1998, we have been developing cranes that prioritize minimal pollution, precision, and efficiency.

In practice, we have learned what works and what doesn't. The result: premium lifting solutions that contribute to your success and can be relied upon

Mennens Cleanroom Cranes

Discover our story.

1998

Mennens Cleanroom Cranes originates from Mennens Dongen: leading hoisting and lifting specialist for industrial applications.

In 1998 we received our first request for two cleanroom cranes here. This application had completely different requirements than for a conventional lifting application.

Research

We investigated how a crane can optimally contribute to the processes in a controlled environment; with the minimum possible dispersion of particles and without the risk of contamination and growth of micro-organisms, among other things.

For this purpose, we conducted research into, among other things, the required (precision) control, suitable hoists, materials, required finishes and surface treatments. All this resulted in our first delivery of two specially produced cleanroom cranes.

Independent

In the years that followed, our cleanroom expertise continued to expand and we gained many valuable practical experiences. This led to the establishment of 'Cleanroom Cranes by Mennens' in 2008, an independently operating part of Mennens Dongen, based in Oirschot and later in Eindhoven.

Since January 1, 2024, 'Mennens Cleanroom Cranes' has been an independent company of the Lifting Solutions Group of Axel Johnson International (Sweden), of which our sister company Mennens Nederland is also part.

Worldwide

We export our advanced cranes worldwide. Leading companies, research institutions and manufacturers in Europe, the United States, South Korea and Taiwan, among others, rely on our products and know-how. Locally we work with renowned representatives and service partners.

Innovation

We have three advanced cleanroom crane designs to our name, the NXT (1998), NXE (2008) and EXE (2018) overhead cranes. Numerous custom variants have been developed and produced based on these crane designs.

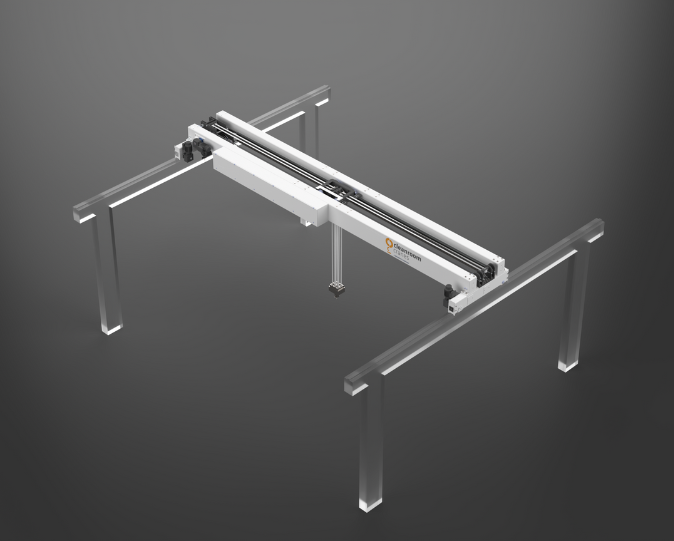

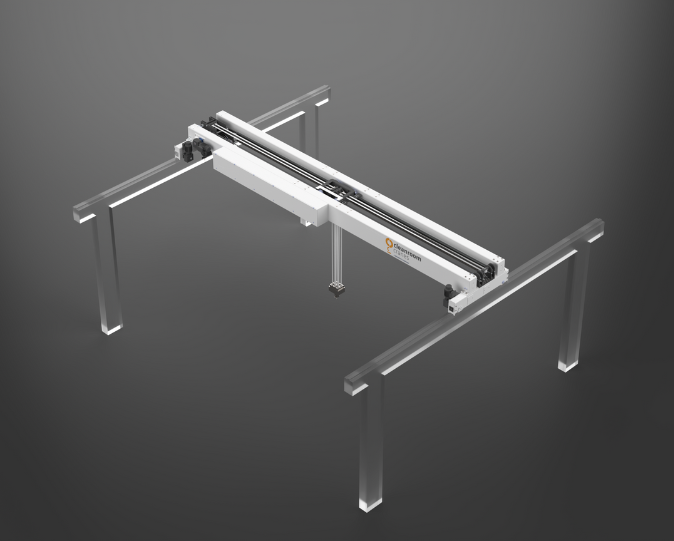

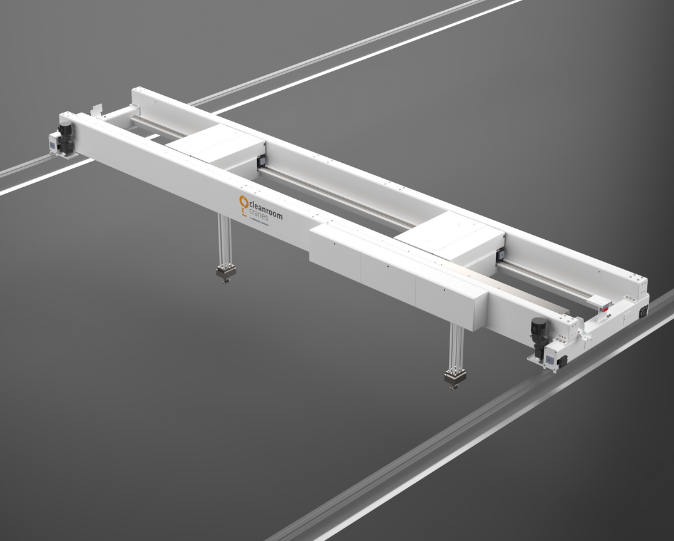

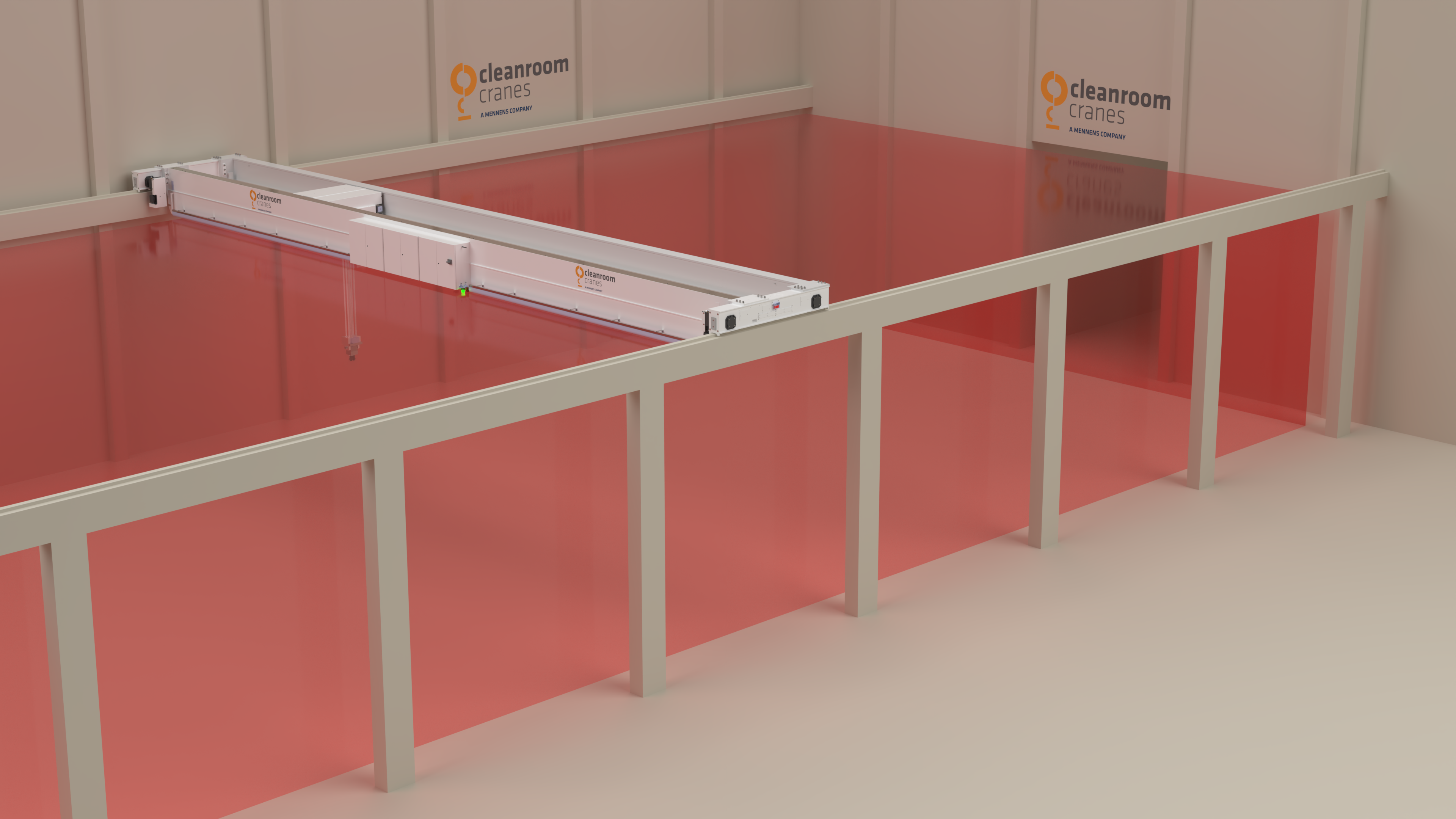

NXT crane

The NXT crane is our 'classic' overhead crane for controlled environments and cleanrooms.

Characteristic of the NXT is its low installation size, which means it can lift and move loads of up to 5,000 kilograms, even in very low spaces.

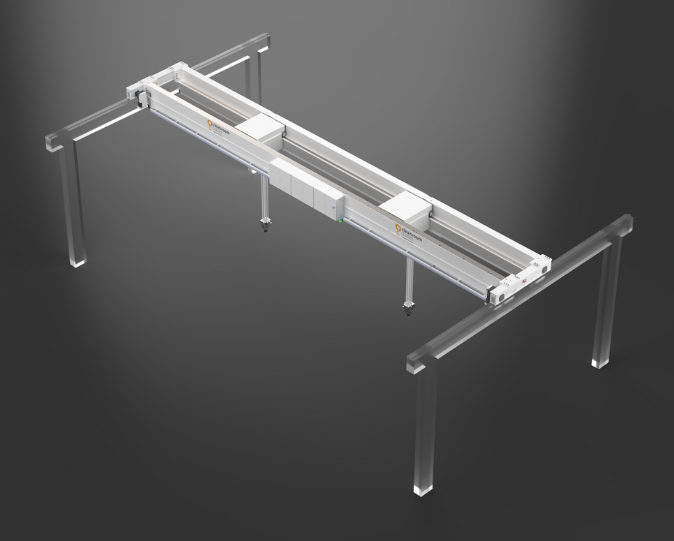

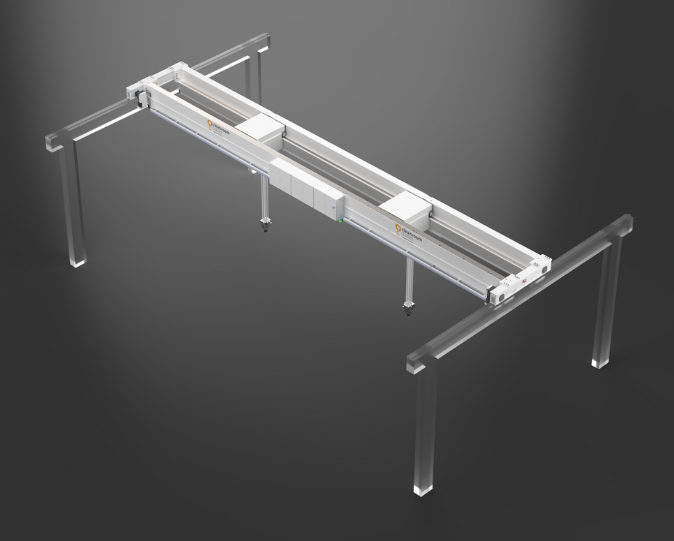

NXE crane

The NXE crane offers flexible options in terms of speed and workload and can optionally be equipped with a frequency controller.

This crane can lift in a Z direction with an accuracy of up to one millimeter; and accurate to two millimeters in the X-Y direction. The lifting weight is four times 5,000 kilograms.

This crane proves its added value, especially in the semiconductor industry, in the ultra-clean positioning of heavy equipment for the production of computer chips.

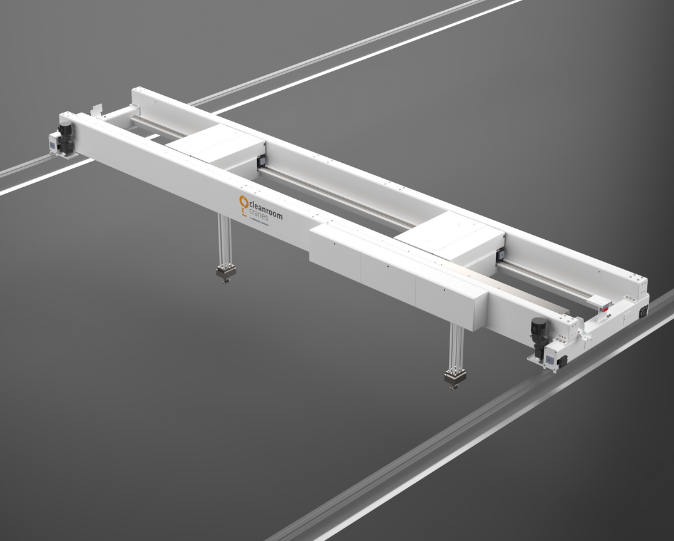

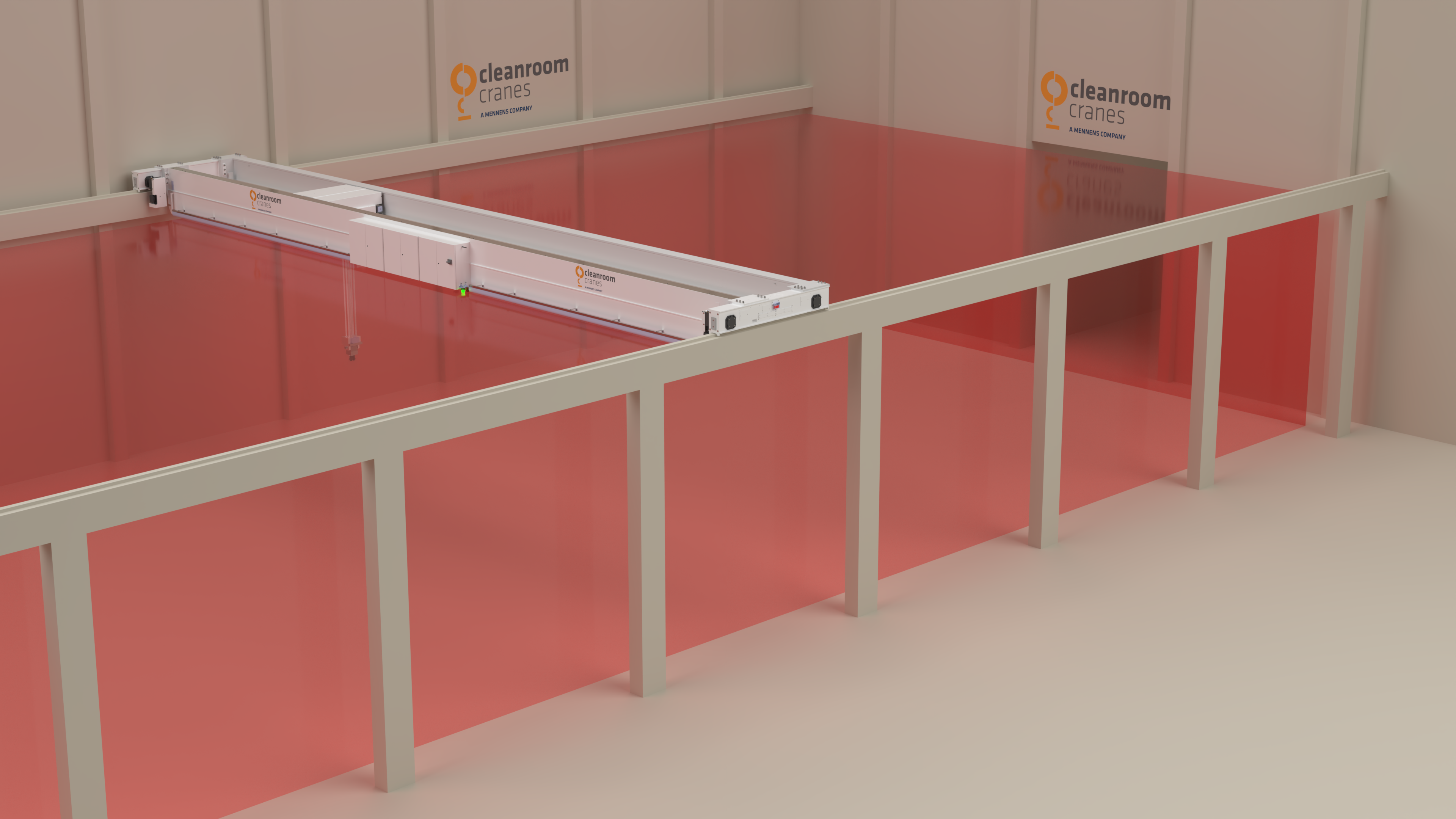

EXE crane

Our flagship product, EXE crane, can lift up to four times 10,000 kilograms, with an accuracy of 0.5 millimetres in any direction.

Like the NXE crane, it also demonstrates its added value in the semiconductor industry in particular.

Our location

You are welcome in our open, modern and bright location at the Innovation District Strijp-T in Eindhoven. This is one of the business parks of Brainport Eindhoven, the innovative heart of the Netherlands. The design, engineering, construction and testing of the cranes take place at our location.

We have now produced hundreds of cleanroom cranes in various configurations on a floor area of no less than 2,800 m2 in 3 spacious halls. From large to compact and from lightweight to heavy.

-

1998

Mennens Cleanroom Cranes originates from Mennens Dongen: leading hoisting and lifting specialist for industrial applications.

In 1998 we received our first request for two cleanroom cranes here. This application had completely different requirements than for a conventional lifting application. -

Research

We investigated how a crane can optimally contribute to the processes in a controlled environment; with the minimum possible dispersion of particles and without the risk of contamination and growth of micro-organisms, among other things.

For this purpose, we conducted research into, among other things, the required (precision) control, suitable hoists, materials, required finishes and surface treatments. All this resulted in our first delivery of two specially produced cleanroom cranes. -

Independent

In the years that followed, our cleanroom expertise continued to expand and we gained many valuable practical experiences. This led to the establishment of 'Cleanroom Cranes by Mennens' in 2008, an independently operating part of Mennens Dongen, based in Oirschot and later in Eindhoven.

Since January 1, 2024, 'Mennens Cleanroom Cranes' has been an independent company of the Lifting Solutions Group of Axel Johnson International (Sweden), of which our sister company Mennens Nederland is also part. -

Worldwide

We export our advanced cranes worldwide. Leading companies, research institutions and manufacturers in Europe, the United States, South Korea and Taiwan, among others, rely on our products and know-how. Locally we work with renowned representatives and service partners.

-

Innovation

We have three advanced cleanroom crane designs to our name, the NXT (1998), NXE (2008) and EXE (2018) overhead cranes. Numerous custom variants have been developed and produced based on these crane designs.

-

NXT crane

The NXT crane is our 'classic' overhead crane for controlled environments and cleanrooms.

Characteristic of the NXT is its low installation size, which means it can lift and move loads of up to 5,000 kilograms, even in very low spaces. -

NXE crane

The NXE crane offers flexible options in terms of speed and workload and can optionally be equipped with a frequency controller.

This crane can lift in a Z direction with an accuracy of up to one millimeter; and accurate to two millimeters in the X-Y direction. The lifting weight is four times 5,000 kilograms.

This crane proves its added value, especially in the semiconductor industry, in the ultra-clean positioning of heavy equipment for the production of computer chips. -

EXE crane

Our flagship product, EXE crane, can lift up to four times 10,000 kilograms, with an accuracy of 0.5 millimetres in any direction.

Like the NXE crane, it also demonstrates its added value in the semiconductor industry in particular. -

Our location

You are welcome in our open, modern and bright location at the Innovation District Strijp-T in Eindhoven. This is one of the business parks of Brainport Eindhoven, the innovative heart of the Netherlands. The design, engineering, construction and testing of the cranes take place at our location.

We have now produced hundreds of cleanroom cranes in various configurations on a floor area of no less than 2,800 m2 in 3 spacious halls. From large to compact and from lightweight to heavy.

Meet our experts

Our fast-growing team consists of more than 50 colleagues with expertise in engineering, production / machine building, project management, quality control, R&D, marketing and sales. We are available to you every day with know-how and smart solutions for your problem.

Marcel Rabenort

Managing Director

Dave van Zandvliet

Operations Director

Danny van Deuzen

Commercial Director

Tjerk Ermen

Manager Production

Jarno Vermunt

Manager Projects

Arend van de Wiel

Project Manager

Abdul Saleh

Project Manager

Paul Schevers

Project Engineer

Benjamin Kock

Project Engineer

Martijn van Mol

Project Engineer

Evelien Bruns

Marketing Manager

Laurelle van der Stee

Marketeer

Timo Totte

Manager Engineering

Koen van Kollenburg

Manager Installation & Service

Leon van den Bergh

Global Installation & Service Expert

Rens van Jole

Foreman / Superintendent

Vacancies

Working on pioneering lifting solutions for cleanrooms and controlled environments for leading clients. In an inspired team that is eager to hear your insights and ideas.

Does that sound good? Then apply via our working at website (only available in Dutch at the moment) for available positions or send us an open application!

News

What is the lifting range of a cleanroom crane?

Lifting a load is the base of any lifting solution in a cleanroom. To define the right lifting...

Read more

Why construction meetings are essential for a flawless crane installation

Why construction meetings are essential for a flawless crane installation Installing a cleanroom...

Read more

More than 25 years of engineering expertise in cleanroom lifting

Since 1888, Mennens has built engineering expertise in lifting technology. Since 2024, Mennens...

Read more-

What is the lifting range of a cleanroom crane?

Lifting a load is the base of any lifting solution in a cleanroom. To define the right lifting...

Read more -

Why construction meetings are essential for a flawless crane installation

Why construction meetings are essential for a flawless crane installation Installing a cleanroom...

Read more -

More than 25 years of engineering expertise in cleanroom lifting

Since 1888, Mennens has built engineering expertise in lifting technology. Since 2024, Mennens...

Read more

Get advice

Our experts are ready to assist you.

.jpg?width=414&height=414&name=Contact%20image%20414x414%20(1).jpg)

.jpg?width=414&height=414&name=Contact%20image%20414x414%20(1).jpg)

Mennens Cleanroom Cranes B.V.

Achtseweg Zuid 161

5651 GW Eindhoven

The Netherlands

T +31(0)88 425 83 00

sales@cleanroomcranes.nl

www.cleanroomcranes.nl