Hoists

The basis of every cleanroom crane. Clean, strong and compact. Electric or manually controlled.

Hoists are at the heart of every crane. Being able to use them safely and with minimal contamination requires a proper design. Our hoists are available in a variety of designs. From clean stainless steel chain hoists to very strong belt hoists.

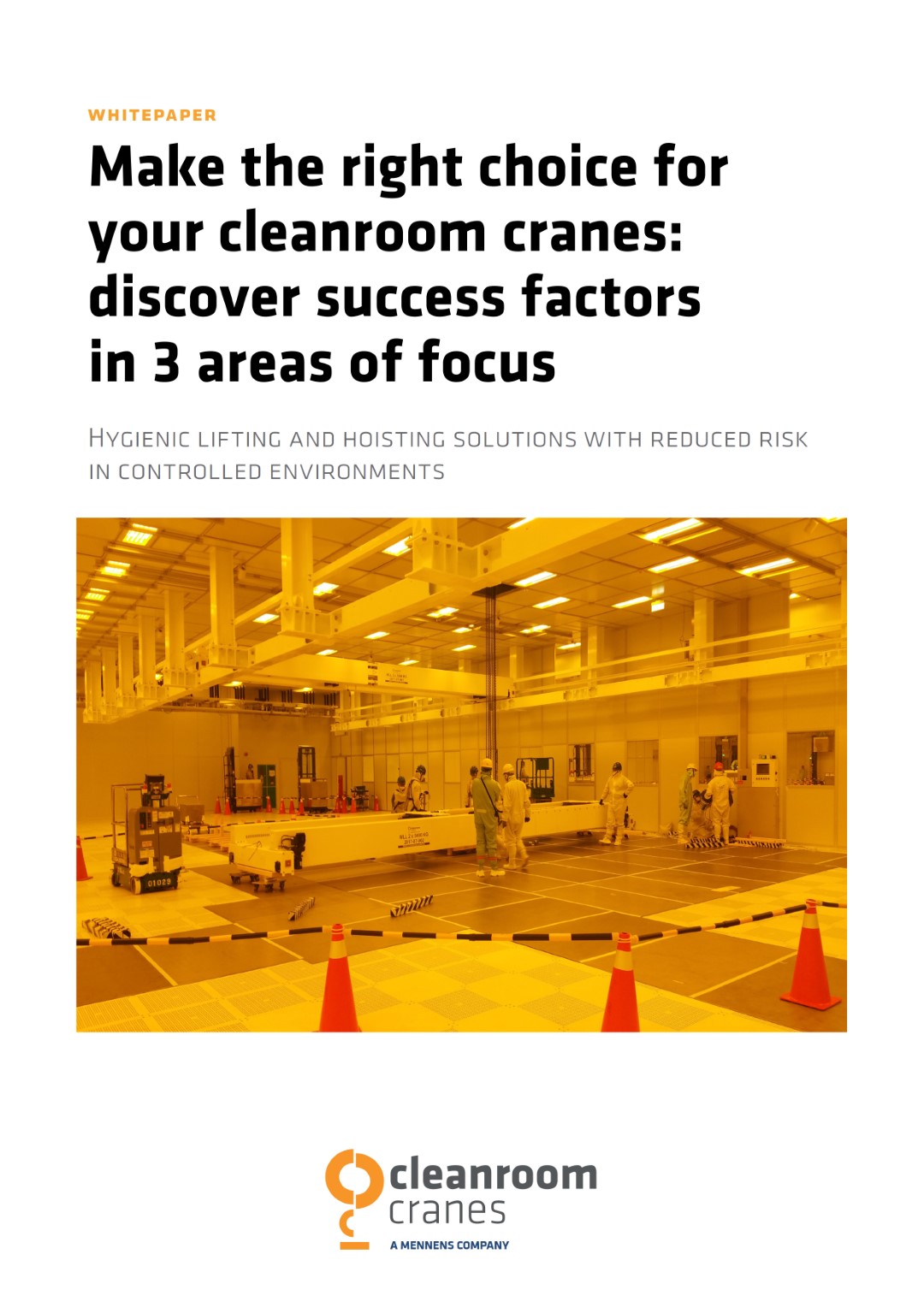

Belthoist CRH1

This universal cleanroom hoist has an ultra-compact design with a hoisting capacity up to 3.500 kg. Configurations include a fixed and remote control. This cleanroom hoist with a powder-coated body and stainless steel 304 components guarantees total cleanliness and non-outgassing and can be delivered with different options:

- Anti-corrosion version

- Fixed suspension / (push/electric) trolley / crane suspension

- Radio remote control

Specifications

- Validated for safe use up to ISO 5 environments according to NEN-EN 14644-1 (3rd party certificate available)

- Standard working load limit (WLL) up to 3.500 kg

- Standard inverter hoisting speed 0,5 to 2 m/min with soft start-stop, micro speed available as option

- Standard hoisting heights between 3,5 to 3,75 meters, higher available on request

- White (Dyneema) lifting belt

- Standard power supply 380-480V – 3 phase – 50-60Hz, 200-240V – 3 phase – 50-60Hz available on request

- Upper and lower (geared) limit switches

- Low voltage 24V control

This universal cleanroom hoist has an ultra-compact design with a hoisting capacity up to 3.500 kg. Configurations include a fixed and remote control. This cleanroom hoist with a powder-coated body and stainless steel 304 components guarantees total cleanliness and non-outgassing and can be delivered with different options:

- Anti-corrosion version

- Fixed suspension / (push/electric) trolley / crane suspension

- Radio remote control

Specifications

- Validated for safe use up to ISO 5 environments according to NEN-EN 14644-1 (3rd party certificate available)

- Standard working load limit (WLL) up to 3.500 kg

- Standard inverter hoisting speed 0,5 to 2 m/min with soft start-stop, micro speed available as option

- Standard hoisting heights between 3,5 to 3,75 meters, higher available on request

- White (Dyneema) lifting belt

- Standard power supply 380-480V – 3 phase – 50-60Hz, 200-240V – 3 phase – 50-60Hz available on request

- Upper and lower (geared) limit switches

- Low voltage 24V control

@2x-1-2.png)

Belthoist BH2

A multifunctional cleanroom hoist for various controlled environments. The BH2 electric belt hoist meets your needs for hoisting power with the strictest cleanliness levels. The hoist can be delivered with different options:

- Anti-corrosion version

- Fixed suspension / (push/electric) trolley / crane suspension

- White (Dyneema) lifting belt

- Radio remote control

Specifications

- Validated for safe use up to ISO7 environments according to NEN-EN 14644-1 (3rd party certificate available)

- Standard working load limit (WLL) between 250 - 2.000 kg

- Standard nickel plated hook/coated block, stainless steel hook/block available as an option

- Standard power supply 380V/400V/415V – 3-phase – 50Hz, 380V/460V – 3-phase – 60Hz available on request

- Standard inverter trolley speed 5 to 20 m/min with soft start-stop

- Upper and lower (geared) limit switches

- Low voltage 48V control

A multifunctional cleanroom hoist for various controlled environments. The BH2 electric belt hoist meets your needs for hoisting power with the strictest cleanliness levels. The hoist can be delivered with different options:

- Anti-corrosion version

- Fixed suspension / (push/electric) trolley / crane suspension

- White (Dyneema) lifting belt

- Radio remote control

Specifications

- Validated for safe use up to ISO7 environments according to NEN-EN 14644-1 (3rd party certificate available)

- Standard working load limit (WLL) between 250 - 2.000 kg

- Standard nickel plated hook/coated block, stainless steel hook/block available as an option

- Standard power supply 380V/400V/415V – 3-phase – 50Hz, 380V/460V – 3-phase – 60Hz available on request

- Standard inverter trolley speed 5 to 20 m/min with soft start-stop

- Upper and lower (geared) limit switches

- Low voltage 48V control

Belthoist BH5 / BH10

Multi-functional belt hoist for all controlled environments. The BH5 electric belt hoist meets your needs for hoisting power with the strictest levels of cleanliness. The BH5 and BH10 offer you the lifting power and robustness of a product designed for cleanroom environments. The hoist can be delivered with different options:

BH5 options

- Electric trolley (for monorail)/ double girder trolley

- Inverter speed hoisting with soft start-stop, various speeds available, micro speed as an option

- Various intelligent features available as an option, enquire for more information

BH5 Specifications

- Validated for safe use up to ISO5 environments according to NEN-EN 14644-1 (test report available)

- Standard working load limit (WLL) between 2.000 - 6.300 kg

- White (Dyneema) lifting belt

- Standard stainless steel hook/block, smooth surface finishing as option

- Various 3-phase – 50/60Hz power supplies available, depending on model, enquire for more information

- Standard 2-speed hoisting, various speeds available (down to 0,6 m/min low speed)

- Standard inverter trolley speed 5 to 20 m/min with soft start-stop, other speeds available as option

- Upper and lower limit switches

- Low voltage 48V control

BH10 options

- Double girder trolley

- Various intelligent features available as option, enquire for more information

BH10 specifications

- Validated for safe use up to ISO 5 environments according to NEN-EN 14644-1 (test report available)

- Standard working load limit (WLL) between 8.000 - 10.000 kg

- White (Dyneema) lifting belt

- Standard stainless steel hook/block, smooth surface finishing as an option

- Various 3-phase – 50/60Hz power supplies available, enquire for more information

- Standard inverter hoisting speed with soft start-stop, various speeds available, micro speed available as an option

- Standard inverter trolley speed with soft start-stop, various speeds available, micro speed available as an option

- Upper and lower limit switches

- Low voltage 48V control

Multi-functional belt hoist for all controlled environments. The BH5 electric belt hoist meets your needs for hoisting power with the strictest levels of cleanliness. The BH5 and BH10 offer you the lifting power and robustness of a product designed for cleanroom environments. The hoist can be delivered with different options:

BH5 options

- Electric trolley (for monorail)/ double girder trolley

- Inverter speed hoisting with soft start-stop, various speeds available, micro speed as an option

- Various intelligent features available as an option, enquire for more information

BH5 Specifications

- Validated for safe use up to ISO5 environments according to NEN-EN 14644-1 (test report available)

- Standard working load limit (WLL) between 2.000 - 6.300 kg

- White (Dyneema) lifting belt

- Standard stainless steel hook/block, smooth surface finishing as option

- Various 3-phase – 50/60Hz power supplies available, depending on model, enquire for more information

- Standard 2-speed hoisting, various speeds available (down to 0,6 m/min low speed)

- Standard inverter trolley speed 5 to 20 m/min with soft start-stop, other speeds available as option

- Upper and lower limit switches

- Low voltage 48V control

BH10 options

- Double girder trolley

- Various intelligent features available as option, enquire for more information

BH10 specifications

- Validated for safe use up to ISO 5 environments according to NEN-EN 14644-1 (test report available)

- Standard working load limit (WLL) between 8.000 - 10.000 kg

- White (Dyneema) lifting belt

- Standard stainless steel hook/block, smooth surface finishing as an option

- Various 3-phase – 50/60Hz power supplies available, enquire for more information

- Standard inverter hoisting speed with soft start-stop, various speeds available, micro speed available as an option

- Standard inverter trolley speed with soft start-stop, various speeds available, micro speed available as an option

- Upper and lower limit switches

- Low voltage 48V control

-Sep-26-2024-11-55-41-7347-AM.png)

Rope hoist FRH

Multi-functional rope hoist for all controlled environments. This rope hoist meets your needs for hoisting power with the strictest levels of cleanliness. The FRH offers you the lifting power and robustness of a product designed for clean room environments. The hoist can be delivered in different models with different options:

- (Push/electric) trolley / double girder trolley

- Inverter speed hoisting with soft start-stop, various speeds available, micro speed as option

- Various intelligent features (e.g. anti-sway/follow-me function) available as an option

Specifications

- Validated for safe use up to ISO 6 environments according to NEN-EN 14644-1 (test report available)

- Standard working load limit (WLL) up to 20.000 kg, depending on cleanroom requirements

- (Dyneema) lifting rope

- Standard nickel plated hook, stainless steel hook available as an option

- Various 3-phase – 50/60Hz power supplies available, enquire for more information

- Standard 2-speed hoisting, various speeds available (down to 0,83 m/min low speed)

- Standard inverter trolley speed 5 to 20 m/min with soft start-stop, various other speeds available, micro speed available as an option

- Upper and lower limit switches

- Low voltage 48V control

Multi-functional rope hoist for all controlled environments. This rope hoist meets your needs for hoisting power with the strictest levels of cleanliness. The FRH offers you the lifting power and robustness of a product designed for clean room environments. The hoist can be delivered in different models with different options:

- (Push/electric) trolley / double girder trolley

- Inverter speed hoisting with soft start-stop, various speeds available, micro speed as option

- Various intelligent features (e.g. anti-sway/follow-me function) available as an option

Specifications

- Validated for safe use up to ISO 6 environments according to NEN-EN 14644-1 (test report available)

- Standard working load limit (WLL) up to 20.000 kg, depending on cleanroom requirements

- (Dyneema) lifting rope

- Standard nickel plated hook, stainless steel hook available as an option

- Various 3-phase – 50/60Hz power supplies available, enquire for more information

- Standard 2-speed hoisting, various speeds available (down to 0,83 m/min low speed)

- Standard inverter trolley speed 5 to 20 m/min with soft start-stop, various other speeds available, micro speed available as an option

- Upper and lower limit switches

- Low voltage 48V control

-3.png)

Electric chain hoist CCH

Electric chain hoist with stainless steel chain with a hoisting capacity of up to 3.200 kg. A dual-speed lifting system with a new lifting nut concept with intermediate teeth leads to a perfect chain drive. Depending on the requirements, this chain hoist can be a good application in various controlled environments of the food, pharma, or medical industries. The hoist can be delivered in different models with different options:

- Anti-corrosion version

- ATEX version

- Hook suspension / (push/electric) trolley / crane suspension

- Inverter speed hoisting with soft start-stop

- IP65/IP66 protection

- Food-safe lubrication

Specifications

- Suitable for use in various ISO environments according to NEN-EN 14644-1, enquire for more information

- Standard working load limit (WLL) up to 3.200 kg

- Stainless steel lifting chain and hook

- Standard lifting height 3 to 15 meters, other heights possible (depending on model and WLL)

- Various 3-phase – 50/60Hz power supplies available, enquire for more information

- Standard 2-speed hoisting, various speeds available (down to 0,83 m/min low speed)

- Standard inverter trolley speed 5 to 20 m/min with soft start-stop

- (emergency) upper and lower limit switch, geared limit switch available as an option

- Low voltage 48V control, some models 24V

Electric chain hoist with stainless steel chain with a hoisting capacity of up to 3.200 kg. A dual-speed lifting system with a new lifting nut concept with intermediate teeth leads to a perfect chain drive. Depending on the requirements, this chain hoist can be a good application in various controlled environments of the food, pharma, or medical industries. The hoist can be delivered in different models with different options:

- Anti-corrosion version

- ATEX version

- Hook suspension / (push/electric) trolley / crane suspension

- Inverter speed hoisting with soft start-stop

- IP65/IP66 protection

- Food-safe lubrication

Specifications

- Suitable for use in various ISO environments according to NEN-EN 14644-1, enquire for more information

- Standard working load limit (WLL) up to 3.200 kg

- Stainless steel lifting chain and hook

- Standard lifting height 3 to 15 meters, other heights possible (depending on model and WLL)

- Various 3-phase – 50/60Hz power supplies available, enquire for more information

- Standard 2-speed hoisting, various speeds available (down to 0,83 m/min low speed)

- Standard inverter trolley speed 5 to 20 m/min with soft start-stop

- (emergency) upper and lower limit switch, geared limit switch available as an option

- Low voltage 48V control, some models 24V

-4.png)

Manual chain hoist HCH/H100

The cleanroom manual chain hoist HCH/H100 is a robust hoist suitable for use in clean rooms. The hoist can be delivered in different models with different options:

- Hook / push trolley suspension

- Load chain in stainless steel

- Top and bottom hook in stainless steel

- Other control and/or lifting heights

Specifications

- Suitable for use in various cleanroom environments, enquire for more information

- Standard working load limit (WLL) up to 2.000 kg

- Standard lifting height 3 meters (between top and bottom hook), control height 2,5 meters

- Hand chain stainless steel

- Load chain nickel plated

- Top and bottom hook nickel-plated

- Covers chrome-plated

- Side plates nickel-plated

- Nuts and rings stainless steel

- 1-fall hoist

The cleanroom manual chain hoist HCH/H100 is a robust hoist suitable for use in clean rooms. The hoist can be delivered in different models with different options:

- Hook / push trolley suspension

- Load chain in stainless steel

- Top and bottom hook in stainless steel

- Other control and/or lifting heights

Specifications

- Suitable for use in various cleanroom environments, enquire for more information

- Standard working load limit (WLL) up to 2.000 kg

- Standard lifting height 3 meters (between top and bottom hook), control height 2,5 meters

- Hand chain stainless steel

- Load chain nickel plated

- Top and bottom hook nickel-plated

- Covers chrome-plated

- Side plates nickel-plated

- Nuts and rings stainless steel

- 1-fall hoist

-4.png)

Dyneema: stretch-resistant, very strong and predictable

We often use Dyneema hoists for our cleanroom cranes. Dyneema consists of very strong, long and lightweight synthetic fibers. This makes it very stretch-resistant: you can rely on a continuously identical lifting characteristic for your process, during the entire lifespan.

In our knowledge paper we explain the benefits Dyneema has for cleanrooms and controlled environments.

We often use Dyneema hoists for our cleanroom cranes. Dyneema consists of very strong, long and lightweight synthetic fibers. This makes it very stretch-resistant: you can rely on a continuously identical lifting characteristic for your process, during the entire lifespan.

In our knowledge paper we explain the benefits Dyneema has for cleanrooms and controlled environments.

Benefits

You use the hoist to move a load vertically. During hoisting, the hoist must emit as few particles as possible.

Electric or manual

Whether you choose electrical or manual control: you remain 'in control'.

ISO compliant

Cleanroom Cranes uses only hoists that demonstrate full compliance with the applicable standards and ISO classifications.

Safe and clean

The hoists limit contamination to the greatest degree possible. Designed and tested for minimum particle dispersion.

Electric or manual

Whether you choose electrical or manual control: you remain 'in control'.

ISO compliant

Cleanroom Cranes uses only hoists that demonstrate full compliance with the applicable standards and ISO classifications.

Safe and clean

The hoists limit contamination to the greatest degree possible. Designed and tested for minimum particle dispersion.

Industries

- Semiconductor industry

- Hightech

- Food industry

- Biotechnology

- Battery industry

- Aerospace

- Aviation

- Semiconductor industry

-

Semiconductor industry

Need to move heavy semiconductor manufacturing equipment accurately, safely and efficiently? Or position light components in exactly the right place?

With over 25 years of experience in the semiconductor industry, you can count on lifting equipment that meets all the requirements. And keep particulate emissions to an absolute minimum in the process.

Hightech

Does your company supply components or parts with ‘cleanliness grade' 4 or 2? We design your lifting equipment so that your production process meets the often highly demanding requirements and specifications set by your partner(s).

At the same time, a cleanroom crane speeds up your process, helping you create greater efficiency and achieve higher profitability.

Food industry

As a player in the food industry, you know full well: everything hinges on food safety. With our hygienic cleanroom cranes, you minimise the risk of potential microorganism formation and contamination.

Our cranes help you comply with laws and regulations, including sector-specific hygiene codes such as those set by the NVWA.

Biotechnology

Pharmaceutical and medical biotechnology processes demand the lowest possible levels of contamination. Preventing contamination is a priority. Process reliability and product safety are also equally important.

Our cleanroom cranes contribute to a safe and traceable process flow with parameters that can be adjusted in detail. They cause minimal to no contamination and prevent the risk of microorganism formation.

Battery industry

Cleanliness and safety are crucial in battery manufacturing. A cleanroom crane allows you to streamline your production process while ensuring that contamination dispersion is kept to a minimum.

Design choices can minimise the dispersion of particles such as dust and trapped contamination. With the right choice of materials, it is also possible to make your lifting equipment explosion-proof.

Aerospace

You need to be able to position or move aerospace objects carefully and appropriately. A non-contaminating and precise crane will help ease your R&D or production process.

Our lifting solutions are safe for use in developing the most sensitive parts, such as satellite components, robotic arms or sun shields.

Aviation

Lift critical aviation parts and components with extreme precision and minimal contamination. Ensuring that every single detail is correct.

Our cleanroom cranes are precise and leave no dust, liquid or paint particles behind. Therefore, cranes contribute significantly to reliability in terms of instruments and engines, etc.

The expertise of Cleanroom Cranes

Engineering

More than 25 years of experience

Customized solutions

Cranes that fit seamlessly into your working environment

Testing

For a flawless and smooth operation of your cleanroom crane

Training

Your employees learn to safely operate the crane

Service

Our experts offer 24/7 service worldwide

TNO provides innovative customization with a unique Cleanroom

“Thanks to the expertise of the technicians, everything went smoothly.”

Teun Brussee

Technical Project Assistant at TNO

TNO was looking for a lifting facility for a new cleanroom to lift a valuable test object into a vacuum boiler.

Two overhead cranes turned out to be necessary. “The installation of the structure and the hanging of the cranes was precision work. The free space up to the ceiling is only a few millimeters.”

Frequently Asked Questions

Why only a hoist?

A hoist is ideal for situations where a lifting mechanism is needed at a fixed location. It provides just a vertical lifting movement ensuring simplicity and efficiency. Perfect for applications without horizontal movements and can be easily integrated into existing crane structures, making it cost-effective and efficient.

What is the maximum lifting capacity?

The lifting capacity of a hoist varies by type and is tailored to specific tasks. Band hoist CRH 1: up to 3,500 kg, BH2: up to 2,000 kg, BH 5: up to 10,000 kg. Rope hoist FRH: up to 20,000 kg. Electric chain hoist CCG: up to 3,200 kg. Hand hoist HCH/H100: up to 2,000 kg.

What materials are possible?

Band and rope hoists lift weight by using Dyneema rope or band, a clean and easy-to-clean material that requires little maintenance and hardly attracts dirt. Dyneema band layers can be stacked on top of each other, unlike Dyneema rope.

Chain hoists are made of stainless steel (RVS), ideal for the pharmaceutical, biotechnology, and food industries due to their cleanability. The choice depends on size, ISO class, type of cleanroom, and lifting weight. Therefore, the best outcome is discussed per situation.

Can't find your question? Contact us using the form below or send us an email.

Need customization?

Our experts will get to work for you.

1. Contact with an expert

We want to get to know you, so that we can advise you based on your situation and needs.

2. Detailed quotation

You will receive a detailed quotation with drawings.

3. Production & Testing

We design, produce and test your cleanroom crane thoroughly.

4. Delivery & Installation

Our professionals deliver and install the crane on-site and carry out a final test.

5. Service

Extend the lifespan of your cleanroom crane with a tailor-made maintenance program.

-

1. Contact with an expert

We want to get to know you, so that we can advise you based on your situation and needs.

-

2. Detailed quotation

You will receive a detailed quotation with drawings.

-

3. Production & Testing

We design, produce and test your cleanroom crane thoroughly.

-

4. Delivery & Installation

Our professionals deliver and install the crane on-site and carry out a final test.

-

5. Service

Extend the lifespan of your cleanroom crane with a tailor-made maintenance program.

Mennens Cleanroom Cranes B.V.

Achtseweg Zuid 161

5651 GW Eindhoven

The Netherlands

T +31(0)88 425 83 00

sales@cleanroomcranes.nl www.cleanroomcranes.nl

Need customization?