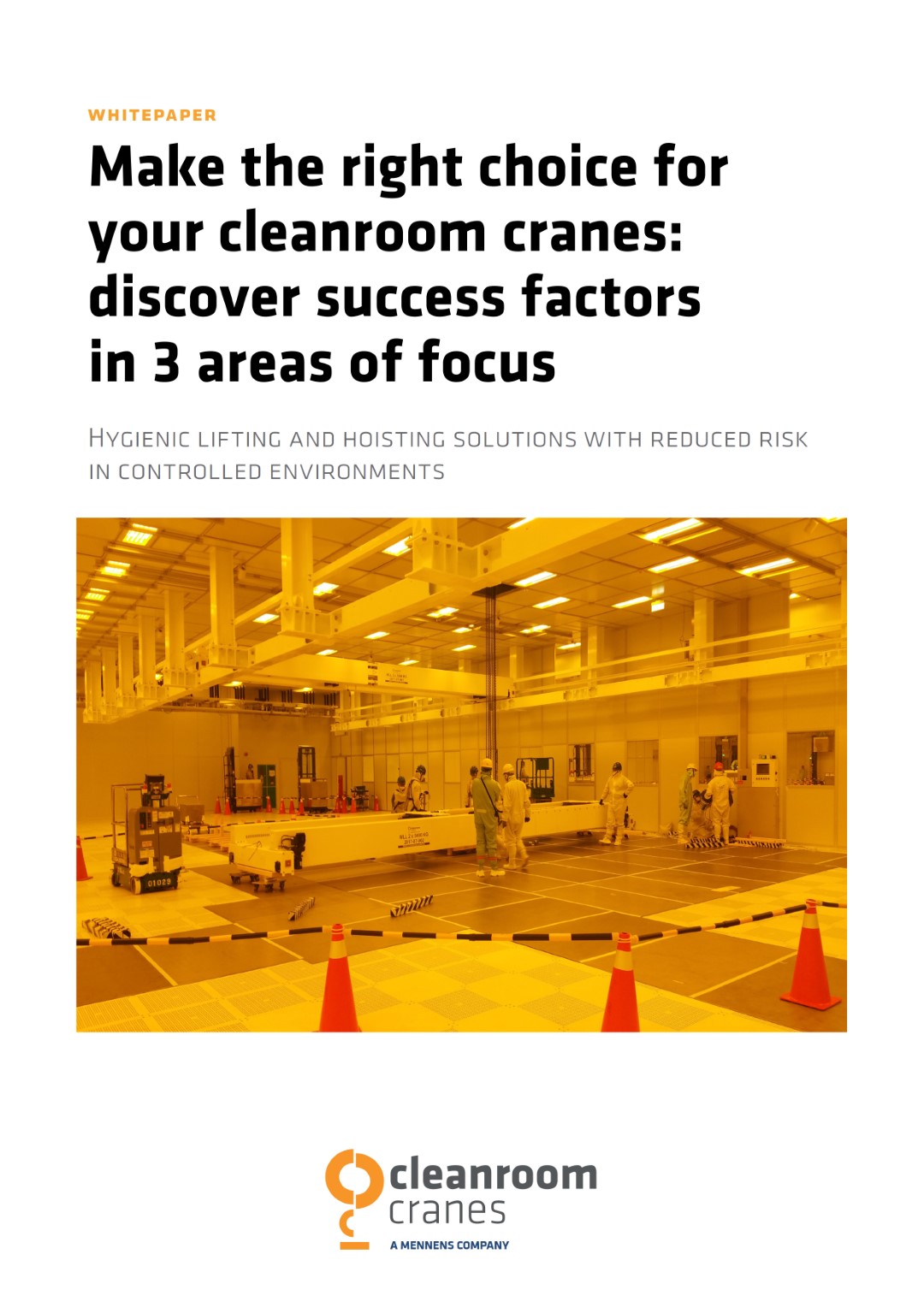

Monorail cranes

Monorail cranes are ideal for repetitive load movements from A to B without covering the entire cleanroom area.

A monorail crane system consists of a beam or guide rail with an attached trolley, offering easy customisation, including curves and transitions. These systems integrate seamlessly with cleanroom doors and locks. Featuring advanced monorail crane hoists, our solutions ensure precision and efficiency, making them perfect for industries like semiconductors and biotechnology.

Your benefits

A monorail crane is always an overhead system. This allows you to hoist your load cleanly, safely and efficiently while not sacrificing a single square metre of workspace.

Customisable

Straight or curved beams? Manual or electrically operated? Anything is possible.

Minimal impact

Easy to fit into any space. Without any major structural modifications.

Space-saving

Our monorail cranes have a low-volume design.

Safe and clean

The cranes prevent contamination to the greatest degree possible. Easy to clean.

ISO compliant

Cleanroom Cranes constructs the monorail crane in accordance with the applicable standards and ISO classification.

Minimum dispersion

Designed and tested for minimum particle dispersion.

Customisable

Straight or curved beams? Manual or electrically operated? Anything is possible.

Minimal impact

Easy to fit into any space. Without any major structural modifications.

Space-saving

Our monorail cranes have a low-volume design.

Safe and clean

The cranes prevent contamination to the greatest degree possible. Easy to clean.

ISO compliant

Cleanroom Cranes constructs the monorail crane in accordance with the applicable standards and ISO classification.

Minimum dispersion

Designed and tested for minimum particle dispersion.

Industries

- Semiconductor industry

- Hightech

- Food industry

- Biotechnology

- Battery industry

- Aerospace

- Aviation

- Semiconductor industry

-

Semiconductor industry

Need to move heavy semiconductor manufacturing equipment accurately, safely and efficiently? Or position light components in exactly the right place?

With over 25 years of experience in the semiconductor industry, you can count on lifting equipment that meets all the requirements. And keep particulate emissions to an absolute minimum in the process.

Hightech

Does your company supply components or parts with ‘cleanliness grade' 4 or 2? We design your lifting equipment so that your production process meets the often highly demanding requirements and specifications set by your partner(s).

At the same time, a cleanroom crane speeds up your process, helping you create greater efficiency and achieve higher profitability.

Food industry

As a player in the food industry, you know full well: everything hinges on food safety. With our hygienic cleanroom cranes, you minimise the risk of potential microorganism formation and contamination.

Our cranes help you comply with laws and regulations, including sector-specific hygiene codes such as those set by the NVWA.

Biotechnology

Pharmaceutical and medical biotechnology processes demand the lowest possible levels of contamination. Preventing contamination is a priority. Process reliability and product safety are also equally important.

Our cleanroom cranes contribute to a safe and traceable process flow with parameters that can be adjusted in detail. They cause minimal to no contamination and prevent the risk of microorganism formation.

Battery industry

Cleanliness and safety are crucial in battery manufacturing. A cleanroom crane allows you to streamline your production process while ensuring that contamination dispersion is kept to a minimum.

Design choices can minimise the dispersion of particles such as dust and trapped contamination. With the right choice of materials, it is also possible to make your lifting equipment explosion-proof.

Aerospace

You need to be able to position or move aerospace objects carefully and appropriately. A non-contaminating and precise crane will help ease your R&D or production process.

Our lifting solutions are safe for use in developing the most sensitive parts, such as satellite components, robotic arms or sun shields.

Aviation

Lift critical aviation parts and components with extreme precision and minimal contamination. Ensuring that every single detail is correct.

Our cleanroom cranes are precise and leave no dust, liquid or paint particles behind. Therefore, cranes contribute significantly to reliability in terms of instruments and engines, etc.

The expertise of Cleanroom Cranes

Engineering

More than 25 years of experience

Customized solutions

Cranes that fit seamlessly into your working environment

Testing

For a flawless and smooth operation of your cleanroom crane

Training

Your employees learn to safely operate the crane

Service

Our experts offer 24/7 service worldwide

Frequently Asked Questions

What is the difference between a monorail and an overhead crane?

Both cranes are perfect to keep your floorspace free. A monorail crane is an overhead system that follows a guide rail attached to the ceiling. This is most suitable for repetitive motions from A to B. You can move your load in X- (horizontal/travel), and Z-direction (vertical/hoist).

With an overhead crane, you have the largest range of motion to move your load. It can be moved in X, Y(horizontal/travel), and Z-direction (vertical/hoist). We can advise you on the best cleanroom crane for your processes. Simply fill in the contact form below.

What is the difference between a monorail and a gantry crane?

A monorail crane is an overhead system that follows a guide rail attached to the ceiling. This is most suitable for repetitive motions from A to B.

Sometimes a fixed crane system is not possible in the existing cleanroom construction. In that case, a mobile crane, such as a gantry crane, is an ideal solution. We can advise you on the best cleanroom crane for your processes. Simply fill in the contact form below.

What is the lifting capacity of a monorail crane?

These monorail cranes are designed and produced varying from 250 kg to 5.000 kg in workload. This is also dependent on the span of the crane in combination with the structural strength and cleanliness grade of the cleanroom they are intended to be in. We can advise you on this. Simply complete the contact form below and we will contact you soon.

What type of monorail cranes exist?

Monorail cranes can use a curved or straight guide rail. They can also be designed to combine with doors and locks in your cleanroom.

Can't find your question? Contact us using the form below or send us an email.

Need customization?

Our experts will get to work for you.

1. Contact with an expert

We want to get to know you, so that we can advise you based on your situation and needs.

2. Detailed quotation

You will receive a detailed quotation with drawings.

3. Production & Testing

We design, produce and test your cleanroom crane thoroughly.

4. Delivery & Installation

Our professionals deliver and install the crane on-site and carry out a final test.

5. Service

Extend the lifespan of your cleanroom crane with a tailor-made maintenance program.

-

1. Contact with an expert

We want to get to know you, so that we can advise you based on your situation and needs.

-

2. Detailed quotation

You will receive a detailed quotation with drawings.

-

3. Production & Testing

We design, produce and test your cleanroom crane thoroughly.

-

4. Delivery & Installation

Our professionals deliver and install the crane on-site and carry out a final test.

-

5. Service

Extend the lifespan of your cleanroom crane with a tailor-made maintenance program.

Mennens Cleanroom Cranes B.V.

Achtseweg Zuid 161

5651 GW Eindhoven

The Netherlands

T +31(0)88 425 83 00

sales@cleanroomcranes.nl www.cleanroomcranes.nl

Need customization?