8 Reasons to choose an overhead crane from Mennens Cleanroom Cranes instead of an industrial crane

Cranes (13) Overhead Cranes (1)

Overhead cranes from Mennens Cleanroom Cranes are used in more controlled environments than just cleanrooms. But why should you choose a cleanroom overhead crane for other applications instead of an industrial variant? In this blog, we explain it in detail.

There are various sectors where the production environment is crucial for the quality or reliability of the end product. Think of the semiconductor industry, but also the aerospace industry, biotechnology, pharmaceutical, high-tech, and the battery production industry. These controlled environments place high demands on the equipment used within them and the behavior of the people working there. Every contamination must be prevented or minimized as much as possible. The impact of lifting and hoisting equipment is often underestimated in this regard.

1 - Contamination by overhead crane

For lifting and moving heavy parts, any overhead crane usually functions fine. However, in a controlled environment, an industrial crane causes various forms of contamination, which can severely affect the safety and quality of production processes. What are the main forms of contamination that can occur?

2 - Particle contamination

An industrial overhead crane is often made of materials susceptible to wear, corrosion, or other forms of degradation, such as steel that can rust or moving parts that can wear out. This leads to the release of particles such as rust, dust, metal particles, or other wear products. These particles get into the air and spread throughout the space, where they can contaminate sensitive products, such as microelectronics, medicines, or food.

3 - Chemical contamination

An industrial overhead crane often uses lubricants, oils, and other chemical substances that are not suitable for cleanroom environments. These substances can evaporate or leak, leading to chemical contamination of the air or surfaces in the space.

4 - Outgassing

Plastics, such as the outer sheath of cabling used in a standard overhead crane, can outgas. Outgassing can affect the air quality in the space and increase the presence of unwanted chemical elements in the air. This can lead to problems in the production of sensitive equipment where the highest air purity is essential.

5 - Biological contamination

Due to their design, many industrial overhead cranes are difficult to keep clean. As a result, they can harbor microbial contaminations. This allows bacteria, fungi, or other microorganisms to spread, which can lead to serious problems in sectors such as biotechnology or pharmaceuticals. Sterility is crucial here, as biological contamination can lead to contaminated products or dangerous infection risks.

6 - Fluid leaks

Oil or other fluids used in industrial lifting and hoisting equipment can leak or drip onto sensitive surfaces or products. This can not only lead to the rejection of a product but also cause serious disruptions in production processes, especially if the fluids contain harmful substances that can affect the products or processes.

7 - Electromagnetic interference (EMI)

Electric motors can generate electromagnetic interference, such as harmonics and noise in the electrical circuit, or electromagnetic radiation. In high-tech production environments, such as semiconductor manufacturing, medical equipment, precision instruments, and laboratories, even minimal EMI can cause disruptions. This results in inaccurate measurements, faulty data analysis, incorrect device operation, product defects, or even damage to the equipment itself.

8 - Vibrations from overhead cranes

Vibrations and noises from industrial overhead cranes can also affect sensitive processes or equipment.

How have we solved this?

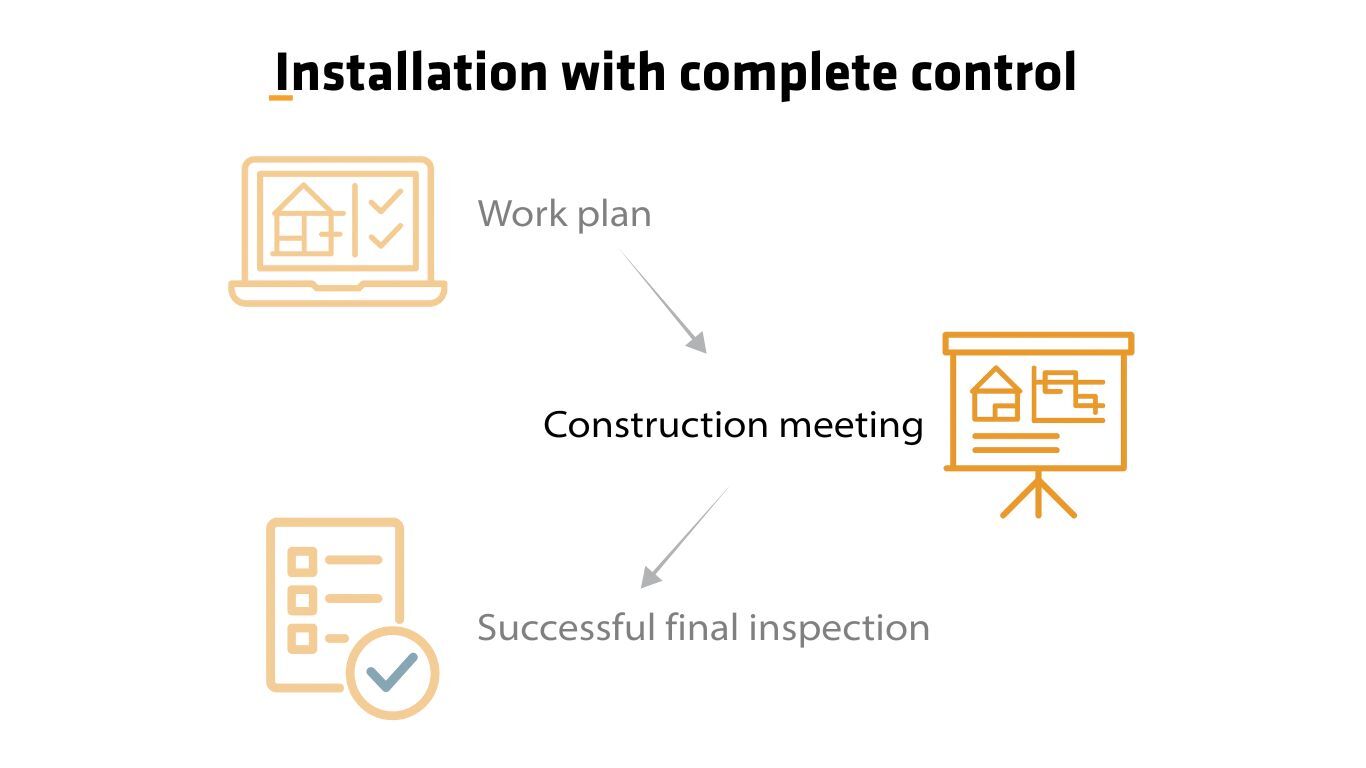

By designing smartly and paying attention to all details, we minimize or prevent all these forms of contamination. As a result, all our lifting solutions are designed to operate within the strict limits of the ISO cleanliness grade of the cleanroom. The lifting solution will not disrupt the cleanroom environment by introducing unwanted contamination. Do you want to know exactly how we do this and why you should choose a crane from Mennens Cleanroom Cranes over a conventional industrial overhead crane? Feel free to contact us. We are convinced that we can offer the perfect overhead crane for your application as well.

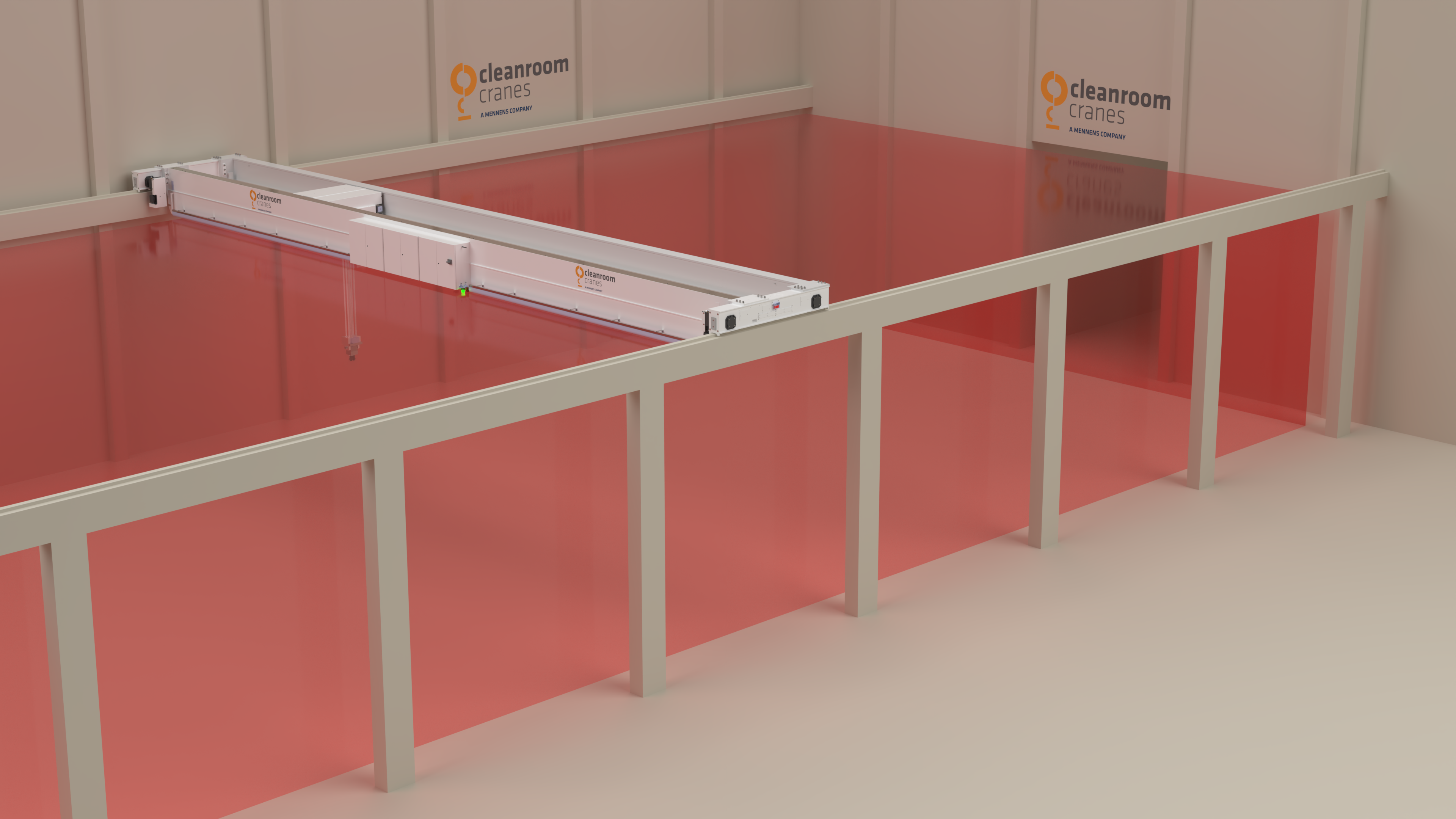

Custom lifting solutions

In addition to overhead cranes, we also design and manufacture monorail cranes, jib cranes, and gantry cranes for controlled environments. Almost every crane is unique. When designing our lifting equipment, we always take your specific situation and strict regulations as a starting point. Why? Because every space is different, and we want to support you in sustainable and efficient business operations.

Preferably, you involve us at an early stage in the (re)design of your cleanroom, laboratory, or other controlled space. This allows us to consider the configuration, construction, and design of your overhead crane, ensuring it fits perfectly in your space. For example, a cleanroom crane needs an environment that supports its lifting capacity and ensures a high degree of cleanliness. By considering this during the design phase, you save valuable time, money, and space.

The advantages of overhead cranes from Mennens Cleanroom Cranes

- Minimal particle dispersion - Designed and tested for minimal particle dispersion

- Safe and Clean - Contamination is minimized to the utmost and easy to keep clean

- ISO Compliant - Every overhead crane meets applicable standards and ISO classifications

- Extremely Accurate - Move very sensitive loads with millimeter precision

- Space Saving - Compact design due to overhead construction

- Worldwide Service - Certified technicians on-site within a few hours, 24/7

- Proactive Maintenance - Always the assurance of a perfectly functioning cleanroom crane

- Inspection and Certification - Periodic (mandatory) inspection and certification by our experts

Are you considering the construction or renovation of one or more controlled environments in the semiconductor, aerospace, high-tech, or battery production industry, or biotechnology environment? Feel free to contact us. We are happy to help you choose the most optimal lifting solution for your application.

.jpg?width=414&height=414&name=Contact%20image%20414x414%20(1).jpg)