Cleanroom particle contamination: origin and displacement

cleanroom equipment (2) contamination (1)

Contamination in a cleanroom can be defined as the presence of substances or gases, such as particles, fluids or airborne molecular, that can have an unwanted effect on the product, process or even a living being. In some circumstances light, magnetism, static and radiation may also be considered contamination.

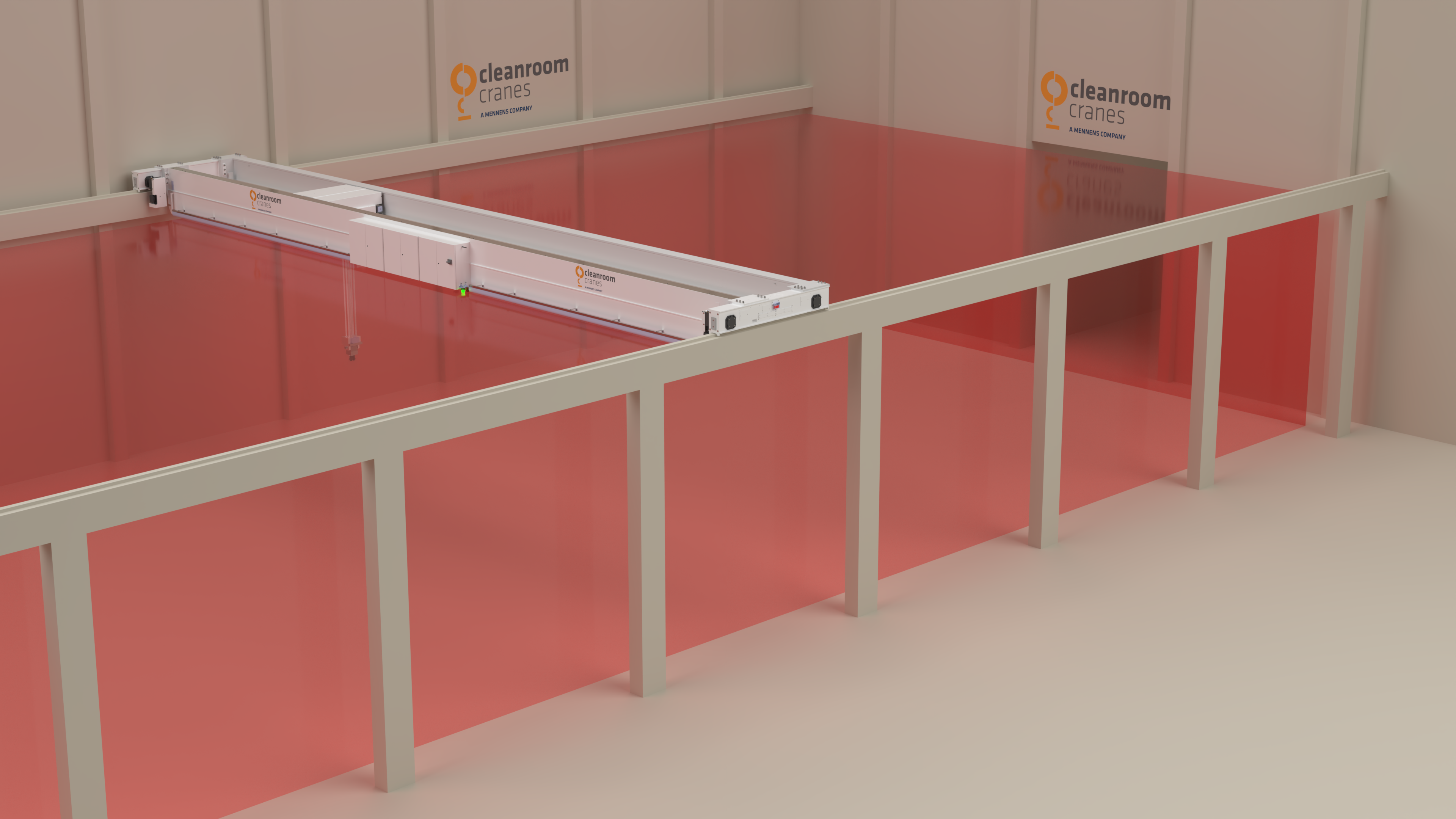

In this blog, we will focus on contamination risks regarding the use of a traditional (overhead ) crane.

Understanding particle contamination

There are particles that originate from the crane, and particles that are released from the building / structure by the crane, in the way of adding energy through vibration or turbulence.

Most cleanrooms are designed with a ceiling-to-floor airflow pattern, typically turbulent. There are some exceptions, like laminar ( horizontal ) flow, and some hybrid solutions in between.

In most cases the flow of air, and gravity, will help particles to deposit at a lower surface—especially particles from 25 micron and larger. The image below shows the time it takes particles from different micron sizes to travel 2,5 meters.

Since the crane is often one of the highest structures in the cleanroom, particles originating from or dislodged by the crane have a high probability of landing on the product or process below. The probability depends on the shape and composition of the particle. For example, a round metallic particle will deposit much faster than a plastic fiber.

Example:

- Metallic particle: if a round metallic particle is released from the crane above the product, the chance is high that it will end up on the surface of the product following gravity

- Plastic fibre: if a fiber from a plastic is released from the same location it can deposit further away due to airflow, and the deposition time will be much longer.

.jpg?width=414&height=414&name=Contact%20image%20414x414%20(1).jpg)