Industries

A more efficient, cleaner and safer process. Discover the added value of a cleanroom crane for your industry.

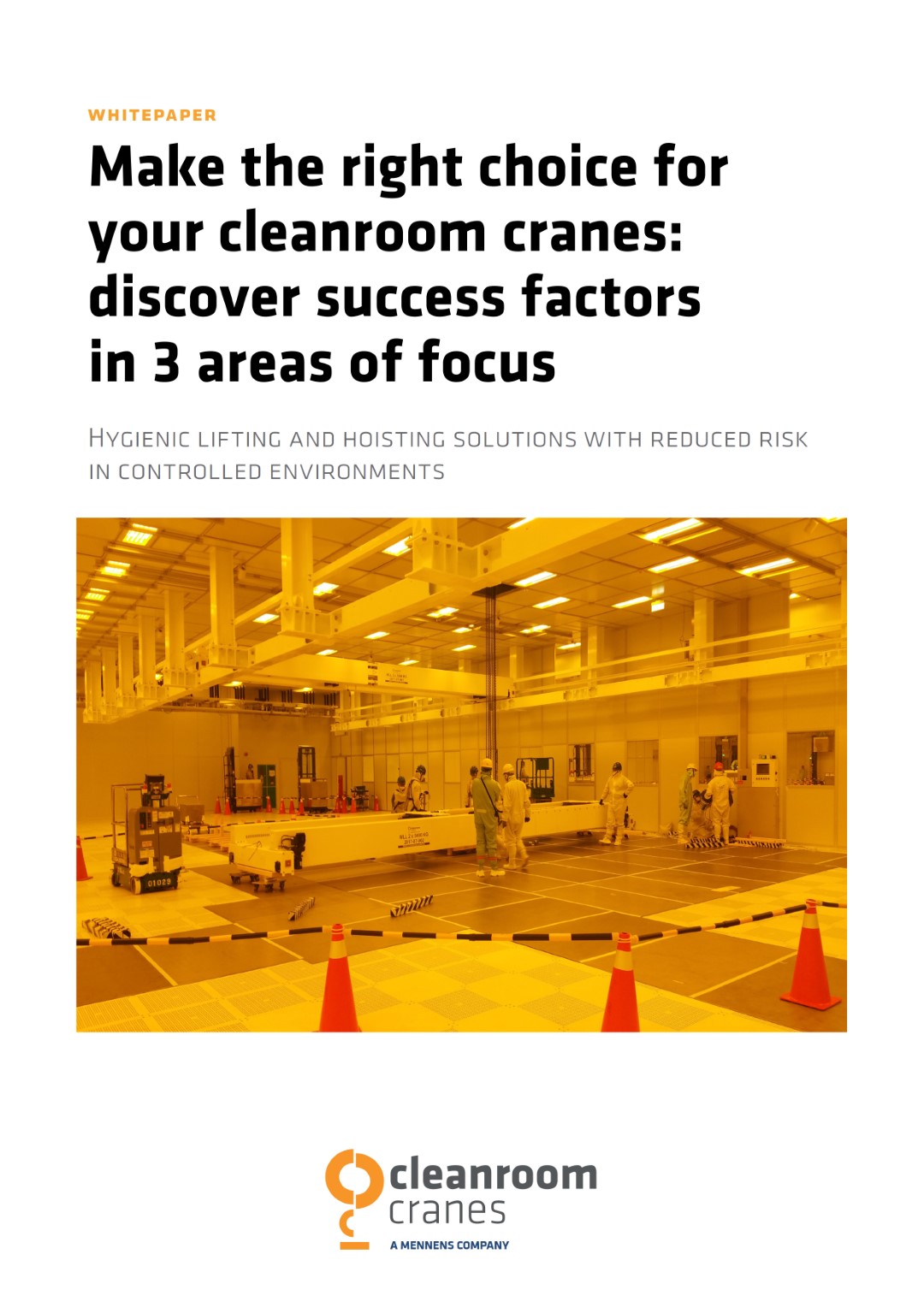

Contact usSemiconductor industry

Need to move heavy semiconductor manufacturing equipment accurately, safely and efficiently? Or position light components in exactly the right place?

With over 25 years of experience in the semiconductor industry, you can count on lifting equipment that meets all the requirements. And keep particulate emissions to an absolute minimum in the process.

Need to move heavy semiconductor manufacturing equipment accurately, safely and efficiently? Or position light components in exactly the right place?

With over 25 years of experience in the semiconductor industry, you can count on lifting equipment that meets all the requirements. And keep particulate emissions to an absolute minimum in the process.

High-tech

Does your company supply components or parts with ‘cleanliness grade' 4 or 2? We design your lifting equipment so that your production process meets the often highly demanding requirements and specifications set by your partner(s).

At the same time, a cleanroom crane speeds up your process, helping you create greater efficiency and achieve higher profitability.

Does your company supply components or parts with ‘cleanliness grade' 4 or 2? We design your lifting equipment so that your production process meets the often highly demanding requirements and specifications set by your partner(s).

At the same time, a cleanroom crane speeds up your process, helping you create greater efficiency and achieve higher profitability.

Food industry

As a player in the food industry, you know full well: everything hinges on food safety. With our hygienic cleanroom cranes, you minimise the risk of potential microorganism formation and contamination.

Our cranes help you comply with laws and regulations, including sector-specific hygiene codes such as those set by the NVWA.

As a player in the food industry, you know full well: everything hinges on food safety. With our hygienic cleanroom cranes, you minimise the risk of potential microorganism formation and contamination.

Our cranes help you comply with laws and regulations, including sector-specific hygiene codes such as those set by the NVWA.

Biotechnology

Pharmaceutical and medical biotechnology processes demand the lowest possible levels of contamination. Preventing contamination is a priority. Process reliability and product safety are also equally important.

Our cleanroom cranes contribute to a safe and traceable process flow with parameters that can be adjusted in detail. They cause minimal to no contamination and prevent the risk of microorganism formation.

Pharmaceutical and medical biotechnology processes demand the lowest possible levels of contamination. Preventing contamination is a priority. Process reliability and product safety are also equally important.

Our cleanroom cranes contribute to a safe and traceable process flow with parameters that can be adjusted in detail. They cause minimal to no contamination and prevent the risk of microorganism formation.

Battery industry

Cleanliness and safety are crucial in battery manufacturing. A cleanroom crane allows you to streamline your production process while ensuring that contamination dispersion is kept to a minimum.

Design choices can minimise the dispersion of particles such as dust and trapped contamination. With the right choice of materials, it is also possible to make your lifting equipment explosion-proof.

Cleanliness and safety are crucial in battery manufacturing. A cleanroom crane allows you to streamline your production process while ensuring that contamination dispersion is kept to a minimum.

Design choices can minimise the dispersion of particles such as dust and trapped contamination. With the right choice of materials, it is also possible to make your lifting equipment explosion-proof.

Aerospace

You need to be able to position or move aerospace objects carefully and appropriately. A non-contaminating and precise crane will help ease your R&D or production process.

Our lifting solutions are safe for use in developing the most sensitive parts, such as satellite components, robotic arms or sun shields.

You need to be able to position or move aerospace objects carefully and appropriately. A non-contaminating and precise crane will help ease your R&D or production process.

Our lifting solutions are safe for use in developing the most sensitive parts, such as satellite components, robotic arms or sun shields.

Aviation

Lift critical aviation parts and components with extreme precision and minimal contamination. Ensuring that every single detail is correct.

Our cleanroom cranes are precise and leave no dust, liquid or paint particles behind. Therefore, cranes contribute significantly to reliability in terms of instruments and engines, etc.

Lift critical aviation parts and components with extreme precision and minimal contamination. Ensuring that every single detail is correct.

Our cleanroom cranes are precise and leave no dust, liquid or paint particles behind. Therefore, cranes contribute significantly to reliability in terms of instruments and engines, etc.

Your benefits

Precision, safety and cleanliness are key in your cleanroom or controlled environment. Our lifting equipment makes a positive contribution here while increasing efficiency.

Seamless process

Further streamline your production process. Increase production and effectiveness.

ISO compliant

Comply with laws, regulations, and ISO classifications. Lifting with minimal to no contamination.

Precision

Lift and move raw materials, components, or equipment with millimetre accuracy.

Frequency-controlled

Set operation speeds and decelerations just like a precision instrument.

Space-saving

Our lifting equipment has a low-volume design.

Low TCO

Carefully considered quality and engineering translate into a low total cost of ownership.

Seamless process

Further streamline your production process. Increase production and effectiveness.

ISO compliant

Comply with laws, regulations, and ISO classifications. Lifting with minimal to no contamination.

Precision

Lift and move raw materials, components, or equipment with millimetre accuracy.

Frequency-controlled

Set operation speeds and decelerations just like a precision instrument.

Space-saving

Our lifting equipment has a low-volume design.

Low TCO

Carefully considered quality and engineering translate into a low total cost of ownership.

Our solutions

-

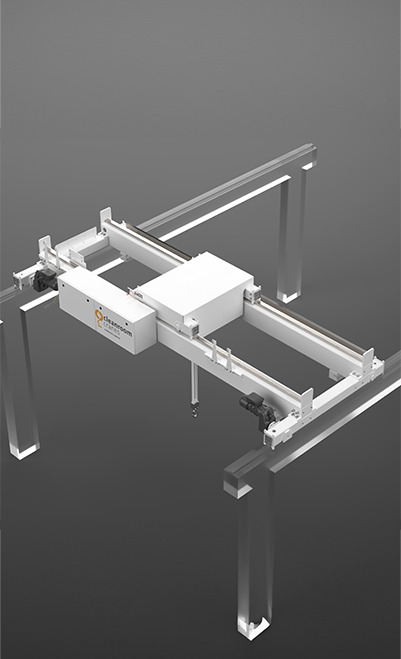

Overhead cranes

Overhead cranesAn overhead crane allows you to cover the entire floor area, while keeping the floor area accessible. This allows you to lift cleanly, efficiently and safely.

Read more -

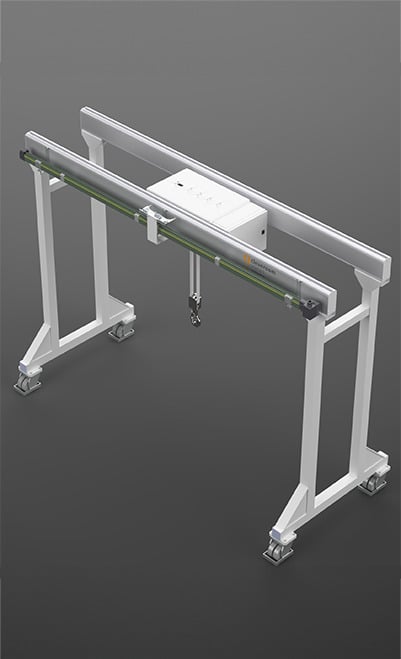

Gantry cranes

Gantry cranesOur mobile gantry cranes allow you to lift cleanly, safely and efficiently in any location. Flexibility, without a fixed crane structure!

Read more -

Jib cranes

Jib cranesDo you perform repetitive lifting operations in your controlled environment? A jib crane proves its value here.

Lees meer -

Monorail cranes

Monorail cranesDo you perform repetitive lifting operations on a section of your total surface area? Discover our monorail cranes.

Read more

Our expertises

Engineering

Our team of top engineers has more than 25 years of experience in designing and developing lifting equipment that minimise contamination. We understand the ISO classifications and laws and regulations within different sectors and countries.

Our years of experience mean we know exactly what works in practice and what doesn’t. The result: premium lifting solutions you can rely on that contribute to your success.

Customised solutions

The conditions in your particular controlled environment are unique. The design of your cleanroom crane depends on a number of factors including the available space, your process, the applicable laws and regulations and ISO classifications.

We design customised cleanroom cranes that comply with all requirements. We also ensure that cranes fit seamlessly into the new or existing working environment.

Testing

Before delivery, we conduct a Factory Acceptance Test (FAT) with the customer to validate the lifting equipment. Cranes are tested on an in-house frame for realistic conditions. After installation, we ensure flawless and smooth operation with a Site Acceptance Test (SAT), in line with the specifications.

Training

We train your employees in crane operation and maintenance.

We provide comprehensive training for your employees, covering different aspects of crane operation and routine maintenance. Our expert instructors will equip your staff with the necessary skills and knowledge to operate cranes safely and efficiently.

Service

Our experts offer 24/7 service worldwide. We carry out inspections and maintenance according to local and international regulations.

Frequently Asked Questions

Why a specialized crane in your cleanroom/controlled environment?

In your cleanroom or controlled environment, everything revolves around cleanliness, precision, and safety. A cleanroom crane demonstrably meets the applicable ISO classification, industry standards, and laws and regulations. Conventional (industrial) lifting equipment does not comply. Using it increases the risk of contamination. Moreover, a conventional lifting system does not operate with sufficient accuracy for use in a cleanroom or controlled environment.

What is special about our cranes?

Our cleanroom cranes are designed to lift accurately and safely with no to extremely minimal spread of contamination. They are made from A-grade components. Every detail has been considered. From the correct execution of the hoist to the shielding of cables and electrical components.

Why is a crane for cleanrooms/controlled environments more expensive than a standard industrial crane?

A cleanroom crane requires a special design and materials that differ from a conventional crane. For example, our cranes are largely made of stainless steel. This is more expensive than steel. Stainless steel is strong and leaves behind no to extremely few particles.

Commonly used design applications include specially developed powder coatings and materials and substances that do not degas or degas minimally (such as special adhesives for information stickers). We have our own R&D department.

We fully equip your cleanroom crane for your process, available space, applicable ISO classification, and industry-specific requirements. Each cleanroom crane is custom-designed.

How do we check if a crane is clean?

Before delivery, an independent expert in contamination control validates the crane in a cleanroom or conditioned environment. Using a special 'laser particle counter', the expert determines the number of particles in the air. This 'counter' sucks in air and thus measures the crane's emissions. The measurement takes place to show how many particles are released during the various operating stages of the crane.

Can't find your question? Contact us using the form below or send us an email.

Get advice

Our experts are ready to assist you.

.jpg?width=414&height=414&name=Contact%20image%20414x414%20(1).jpg)

.jpg?width=414&height=414&name=Contact%20image%20414x414%20(1).jpg)

Mennens Cleanroom Cranes B.V.

Achtseweg Zuid 161

5651 GW Eindhoven

The Netherlands

T +31(0)88 425 83 00

sales@cleanroomcranes.nl

www.cleanroomcranes.nl

.jpg?width=401&height=659&name=Tooling%20slider%20(2).jpg)