News

Interview with Regio Business - Keeping up with the complex questions

Recently, we were interviewed by Regio Business, a magazine that focuses on the manufacturing...

Read more

Cleanroom cranes compliant worldwide

Even if you have the most advanced cleanroom crane built, if it is not certified for your region or...

Read more

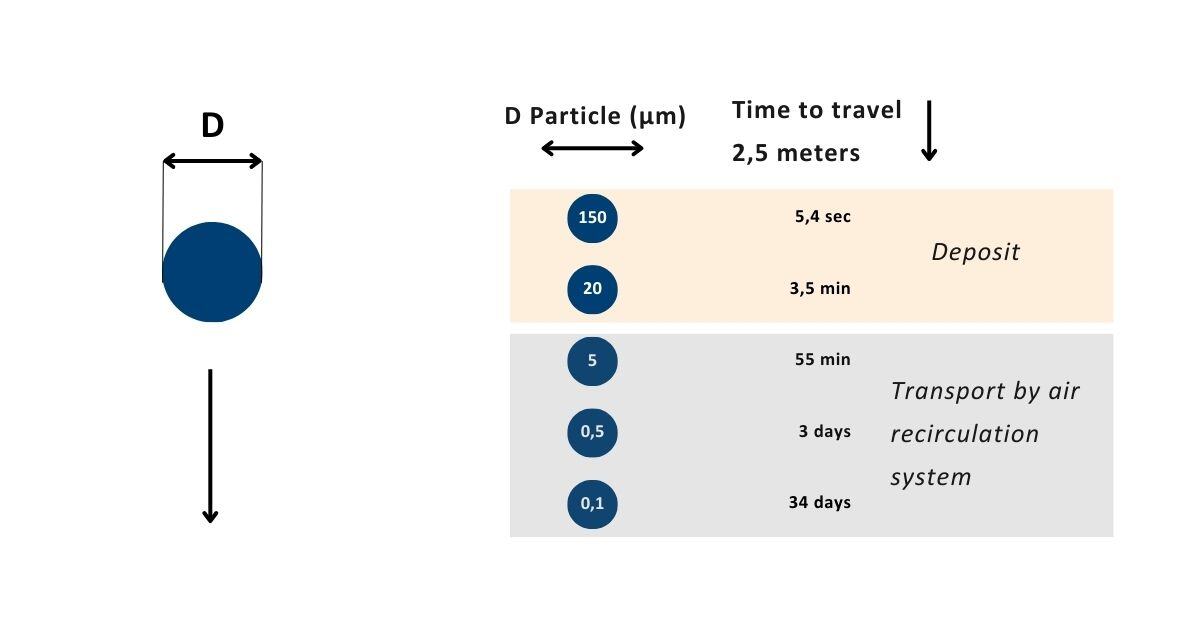

Cleanroom particle contamination: origin and displacement

Contamination in a cleanroom can be defined as the presence of substances or gases, such as...

Read more

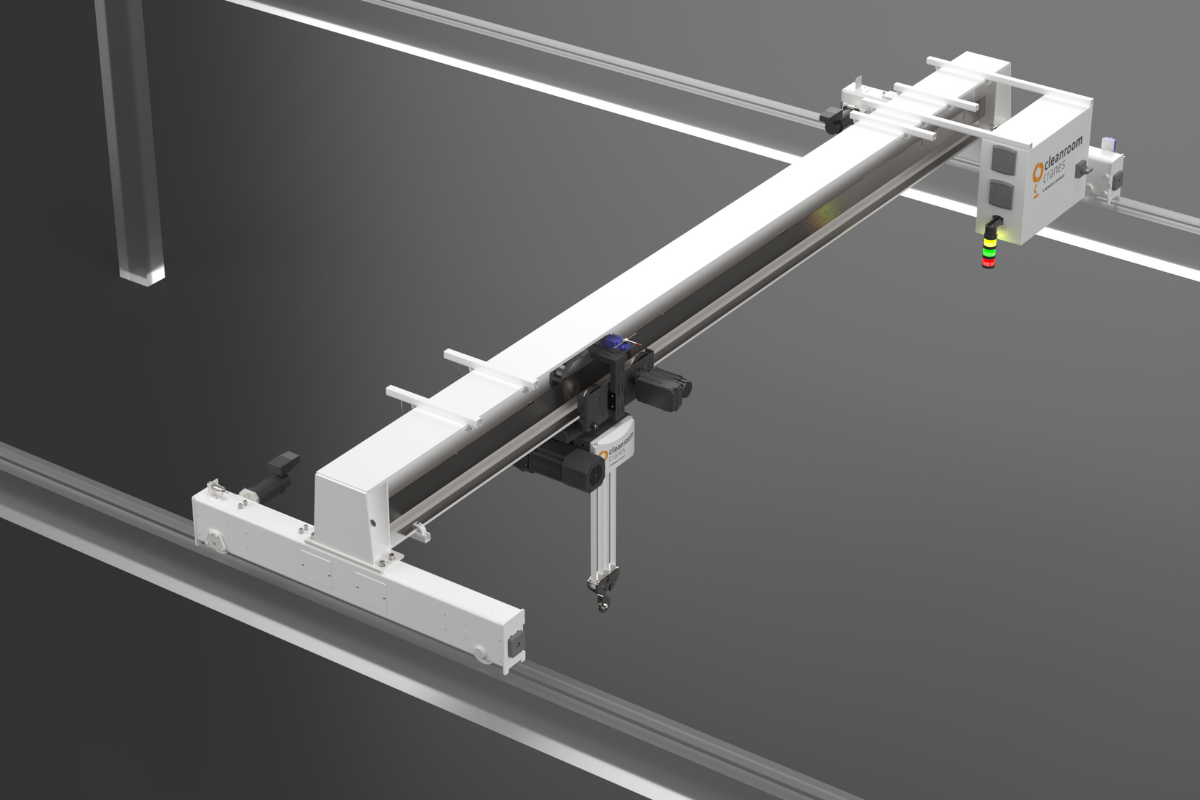

8 Reasons to choose an overhead crane from Mennens Cleanroom Cranes

Overhead cranes from Mennens Cleanroom Cranes are used in more controlled environments than just...

Read more

New Knowledge paper: Clean, compact and reliable lifting with the Dyneema sling

In your cleanroom or controlled environment, cleanliness, safety and precision are paramount. If...

Read moreGet advice

Our experts are ready to assist you.

.jpg?width=414&height=414&name=Contact%20image%20414x414%20(1).jpg)

.jpg?width=414&height=414&name=Contact%20image%20414x414%20(1).jpg)

Mennens Cleanroom Cranes B.V.

Achtseweg Zuid 161

5651 GW Eindhoven

The Netherlands

T +31(0)88 425 83 00

sales@cleanroomcranes.nl

www.cleanroomcranes.nl