New knowledge paper: Clean, compact and reliable lifting with the Dyneema sling

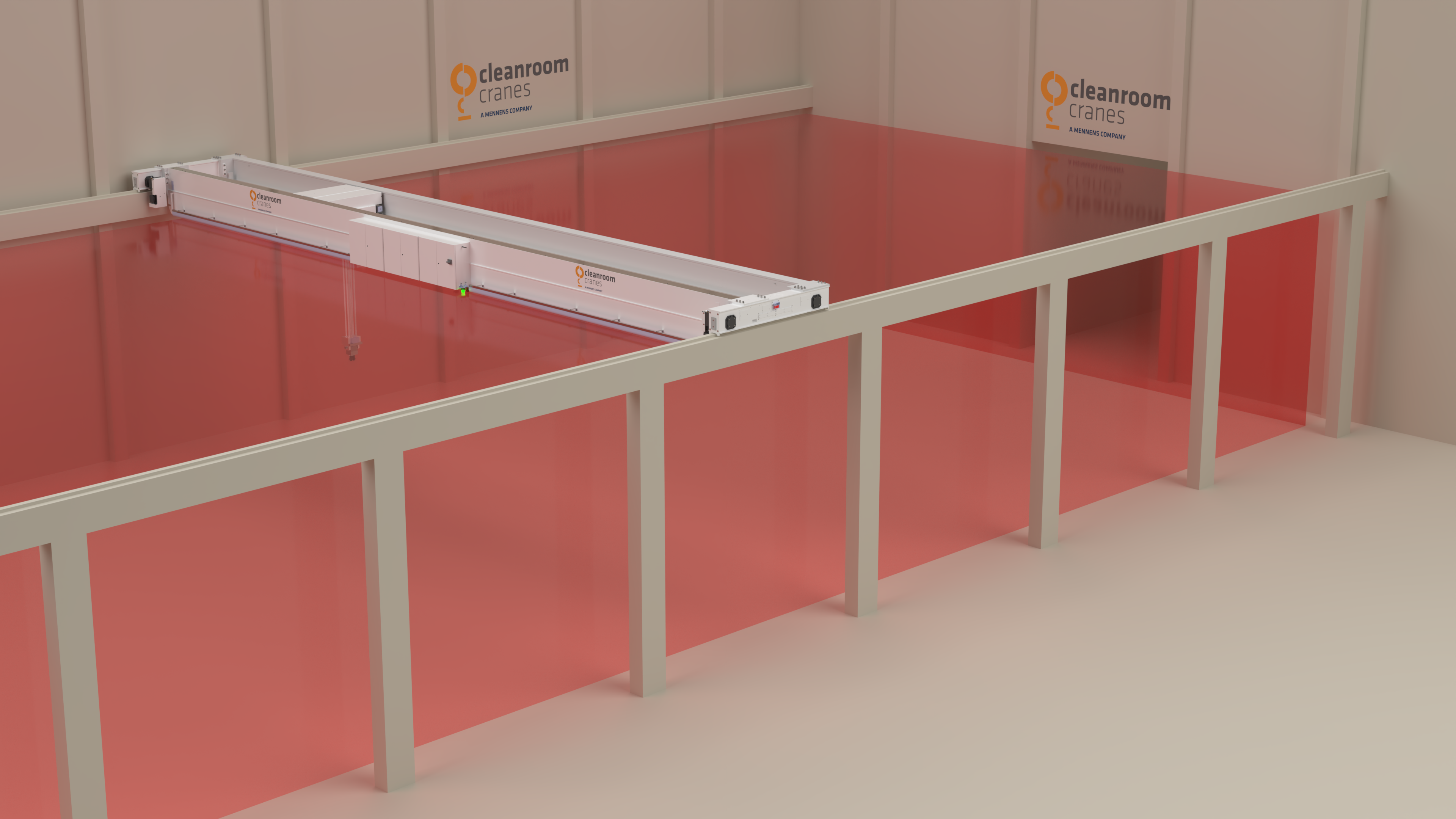

In your cleanroom or controlled environment, cleanliness, safety and precision are paramount. If you use a crane here, then it is crucial for the crane to limit the generation of contamination as much as possible and for it to be extremely reliable. Many factors come into play here. One of them is selecting the right material for the lifting equipment in the hoist.

Hoists are the lifting mechanism for your cleanroom crane. To lift safely and efficiently with as little contamination as possible, it is essential for you to choose the execution class that meets the requirements, standards and ISO classifications that apply to your cleanroom. You can choose lifting equipment such as chain, rope and sling hoists, produced from either metal or synthetic fibers.

Dyneema sling

This lifting sling offers a myriad of remarkable advantages for most industries. The sling has low stretch characteristics, high strength and is predictable. The sling also attracts little to no dirt. Dyneema slings are manufactured from synthetic fibres. This makes the sling ideal for the following sectors:

- Semiconductor industry

- High-tech

- Aerospace

- Aviation

.jpg?width=414&height=414&name=Contact%20image%20414x414%20(1).jpg)