Crane track, crane and trolley with hoist: a clear explanation

Cranes (13)

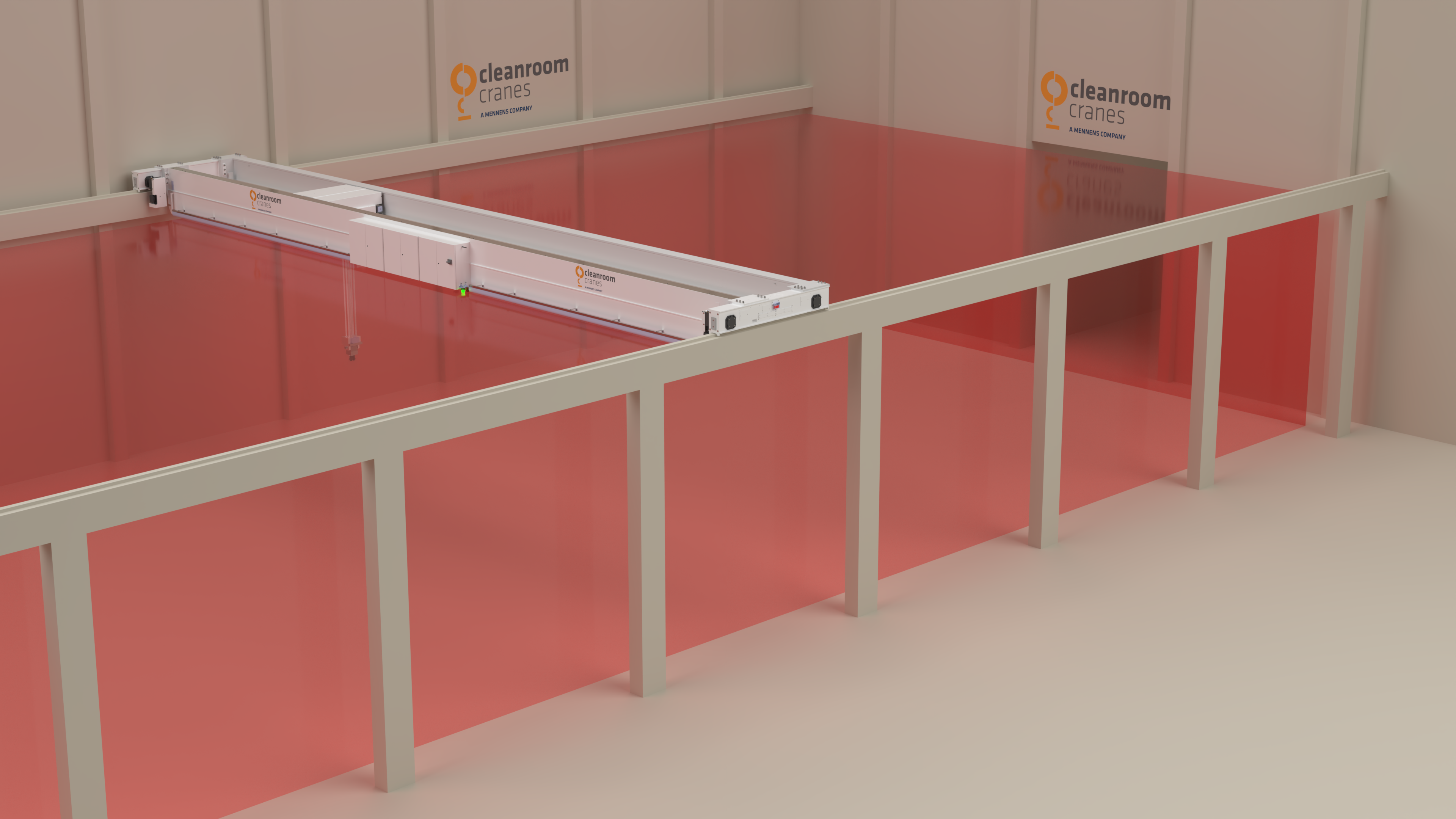

At first sight, a cleanroom crane appears as one complete system. In reality, it is made up of several components that work together to move loads with precision and control.

At first sight, a cleanroom crane appears as one complete system. In reality, it is made up of several components that work together to move loads with precision and control.

The main elements are the crane track, the crane and the trolley with hoist. Together, they form the crane assembly, which allows clean and precise load handling in controlled environments where reliability and accuracy are essential, such as high-tech manufacturing, pharmaceutical production and medical device assembly.

The crane track is the fixed path that guides the movement of the crane assembly. It is built into the structure of the building and defines the path of movement through the workspace.

The track provides a stable foundation for the crane to run on.Its accuracy and rigidity are essential for reliable operation of the entire system.

When properly aligned, the track prevents skewing or uneven loading and helps maintain the precision and long service life of the crane.

The crane links both sides of the crane track through the end truck. The crane supports the weight of the trolley with hoist and the load. The crane spreads the forces evenly across the crane track and forms the core of the crane assembly.

In cleanroom applications, the crane is made of coated steel that meets cleanroom requirements. The smooth, closed surface keeps dust and particles from settling, helping the system remain clean and stable even during continuous use in an ISO-classified environment.

Each crane is designed and finished to match the required span and level of precision. This provides a stable base for the trolley to move along the crane smoothly, without deformation or vibration that could reduce accuracy.

The trolley is the moving part that travels between the girders. It carries the hoist and performs the actual lifting movement. As it moves along the crane, the hoist positions the load precisely within the working area of the crane.

In cleanroom environments, the trolley is designed for controlled and accurate movement. The wheels and bearings allow a steady motion so that loads can be lifted and placed safely and with precision. The smooth, closed design prevents dust and particles from settling, keeping the system clean and reliable in controlled environments.

The crane track, crane and trolley with hoist together form the crane assembly, the system that enables controlled lifting and movement in a cleanroom. Each part has its own function, and only when they work together does the crane achieve the level of precision and cleanliness required in these environments.

Understanding the role of each component helps to see how a cleanroom crane is built and why alignment between the parts is so important. When the crane track is stable, the crane is aligned correctly and the trolley with hoist moves smoothly, the lifting process remains accurate and free from contamination.

At Mennens Cleanroom Cranes, every crane assembly is developed with attention to precision and long-term reliability. Each component is designed to meet the demands of controlled environments where accuracy and cleanliness are essential.

The result is a lifting system that performs consistently within the strict conditions of high-tech manufacturing, pharmaceutical production and medical technology.

Want to learn more about how crane assemblies are designed for controlled environments?

Explore our cleanroom crane solutions or contact our specialists for technical guidance.

The crane track is the fixed path on which the crane assembly travels. The crane connect both sides of the runway and support the trolley. The hoist of the trolley performs the lifting motion and moves the load within the working area.

A cleanroom crane is used to lift and move loads in environments that require absolute cleanliness and precision, such as high-tech manufacturing, pharmaceutical processes and medical device assembly.

Yes, that is possible. In new cleanrooms, the components are usually designed as a single system. In existing installations, individual parts can be replaced or adjusted, provided that the technical and cleanliness requirements are maintained.

Lifting a load is the base of any lifting solution in a cleanroom. To define the right lifting solution, several aspects need to be considered. Two key concepts play a role; the lifting area and the lifting range. How these are defined and applied depends on the type of crane used.

Why construction meetings are essential for a flawless crane installation

Installing a cleanroom crane requires precision—not only in steel, but also in planning. Construction meetings provide the overview needed to identify bottlenecks early and prevent delays.

Since 1888, Mennens has built engineering expertise in lifting technology. Since 2024, Mennens Cleanroom Cranes operates as an independent company, with a clear focus on lifting solutions for cleanrooms and controlled production environments.

In the article below, published in the Mennens magazine, we look back at the origins of Cleanroom Cranes and ahead.

A cleanroom crane is never installed without planning. Behind every successful installation lies a work plan that brings together technology, scheduling, and collaboration. This silent force repeatedly proves decisive for controlled execution without surprises

Our experts are ready to assist you.

.jpg?width=414&height=414&name=Contact%20image%20414x414%20(1).jpg)

.jpg?width=414&height=414&name=Contact%20image%20414x414%20(1).jpg)

Achtseweg Zuid 161

5651 GW Eindhoven

The Netherlands

T +31(0)88 425 83 00

sales@cleanroomcranes.nl

www.cleanroomcranes.nl