Designing ground-breaking cleanroom cranes: this is how we do it

Cranes (13)

By: Martijn Verweij, Mechanical Engineer

Before you can receive your brand new cleanroom crane, it must of course be designed and built first. As a Mechanical Engineer, I take care of the design process together with my colleagues. A meticulous process, that involves many different steps. Curious how that works exactly? I will gladly tell you more about it.

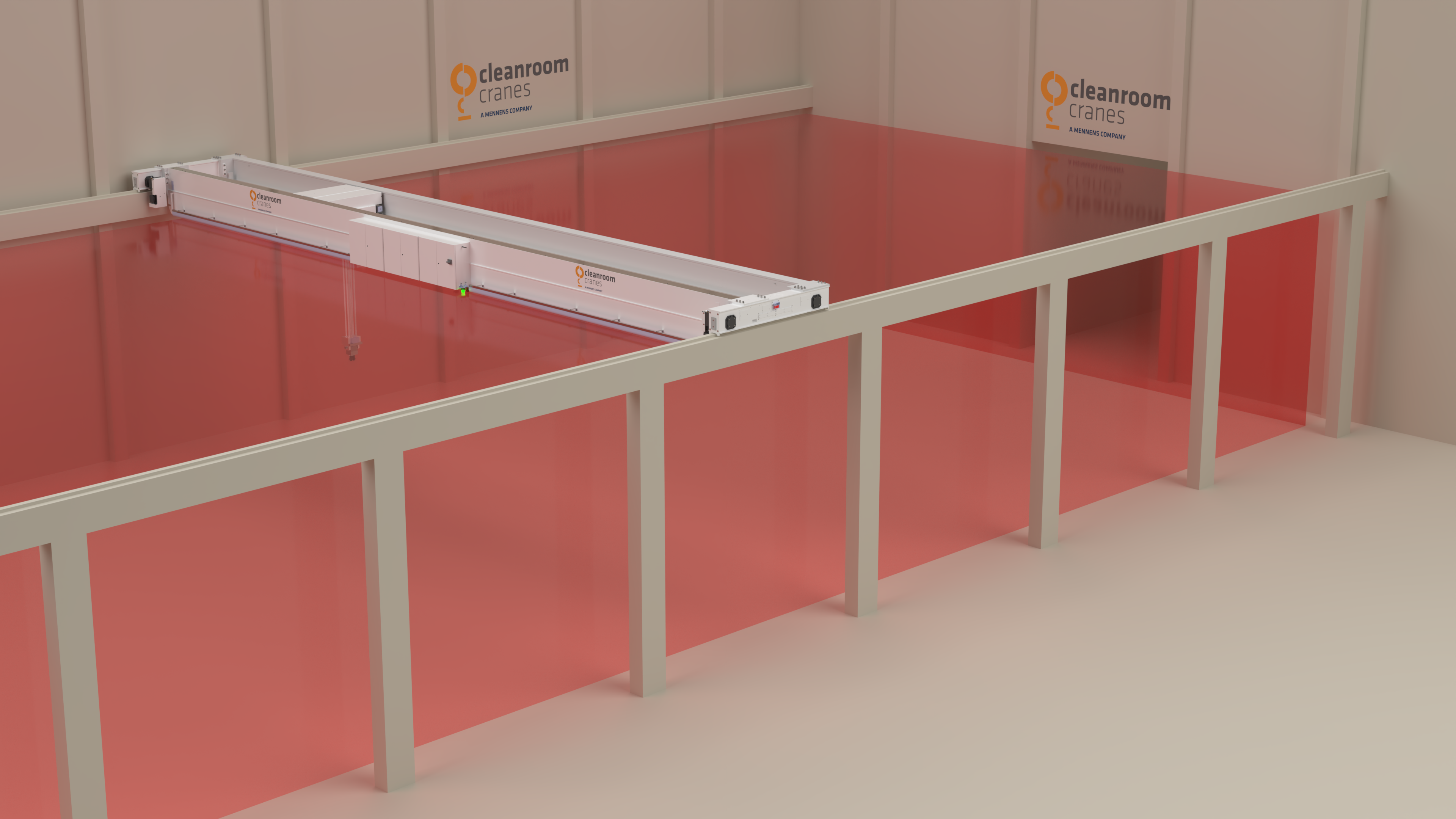

As you may already know, at Cleanroom Cranes we design and assemble (customized) lifting solutions for clean (production) environments. Think of cleanrooms for the semiconductor industry, food industry, healthcare, pharmaceutical industry, and aerospace.

Specific standards and laws and regulations

All these industries have their own specific laws and regulations. And each cleanroom (class) has its own (very strict) specific requirements. For example, in the semiconductor industry, it is important that the crane contamination is kept to a minimum and that it is very accurate. In the pharmaceutical and food industries, the emphasis lies not only on limiting contamination but also on preventing the dispersion of small particles and the cleanliness of the crane.

Inventory

At Cleanroom Cranes we know - as you do - the requirements and of course take them into account from the design phase onwards. First of all, together we map out: what requirements does the crane have to meet? At what speeds can the crane lift and hoist? What load will be lifted? In what way? Only horizontally or also vertically? How polluting is the crane allowed to be? How easy should it be to clean? What dimensions does the crane need to have?

Pre-engineering

Based on the requirements, I then determine whether standard components suffice or whether a customized solution is needed. And which system might fit the crane. In the case of a customized solution, we almost always start with pre-engineering. You then receive an overview in advance of the choices made, the expected process steps, lead time, and costs of the cleanroom crane.

Detail engineering

During the detail engineering phase, we really get down to work. In this phase, we design the complete crane. From brackets and (protective) covers to electrical components and hoists. Everything is included. During the design phase, I pay close attention to every detail. Think about the positioning level, the cleanliness, possible coatings, the material of the crane, and the components.

Depending on the wishes, I also make sure that there are not too many open seams, that certain parts are well covered, that the crane is easy to clean, and that no parts rub against each other unnecessarily.

Plenty of innovation

In recent years, I have had the opportunity to design many ground-breaking cranes. One of them was a very compact built-in crane that had to be installed in a machine. With a span of 2 to 2.5 meters, it was a delicate operation. And for one of our clients in the semiconductor industry, we developed the most precise crane currently available. To give you an idea: the crane can be controlled in steps of half a millimeter, with an accuracy of 0.1 millimeters over a meter. A fantastic result.

About Martijn Verweij

Martijn Verweij has been enriching the Cleanroom Cranes team since 2019 as a Mechanical Engineer. In this role, he is at the heart of the most specialized cleanroom cranes in the world. Based on the requests that come in, he designs cranes to measure or delivers a more standardized design. What makes his job so great according to Martijn? The precision and technical content.

.jpg?width=414&height=414&name=Contact%20image%20414x414%20(1).jpg)