A cleanroom crane with a specific ISO value? Find out how it works

ISO class (1) ISO value (1)

By: Jarno Vermunt, Manager Projects

In my role as a project manager at Mennens Group, I frequently engage with organizations looking to enhance their cleanrooms with lifting equipment. What strikes me is that they are often looking for a crane with the same ISO value as that of the cleanroom. However, such a crane does not exist. Allow me to explain why.

The reasoning seems plausible: if you have an ISO 5 cleanroom, you would need an ISO 5 cleanroom crane as well. But it doesn't work that way. The ISO classification for cleanrooms indicates the maximum allowable quantity of particles per cubic meter that may be present in the cleanroom at any given time.

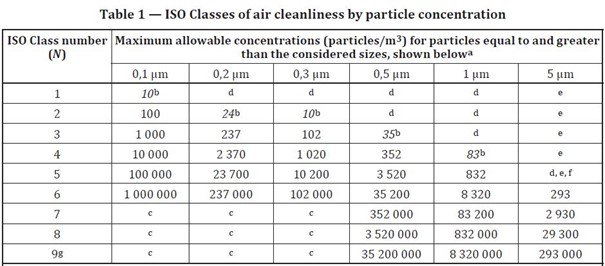

Maximum number of particles

An example: ISO class 5 represents a cleanroom in which a maximum of 100,000 particles of 0.1 micrometres (µm) per cubic metre of air are present. Or 23,700 particles of 0.2 micrometres per cubic metre of air. Please refer to the table below for all classifications and the maximum number of particles:

No fixed set of parameters

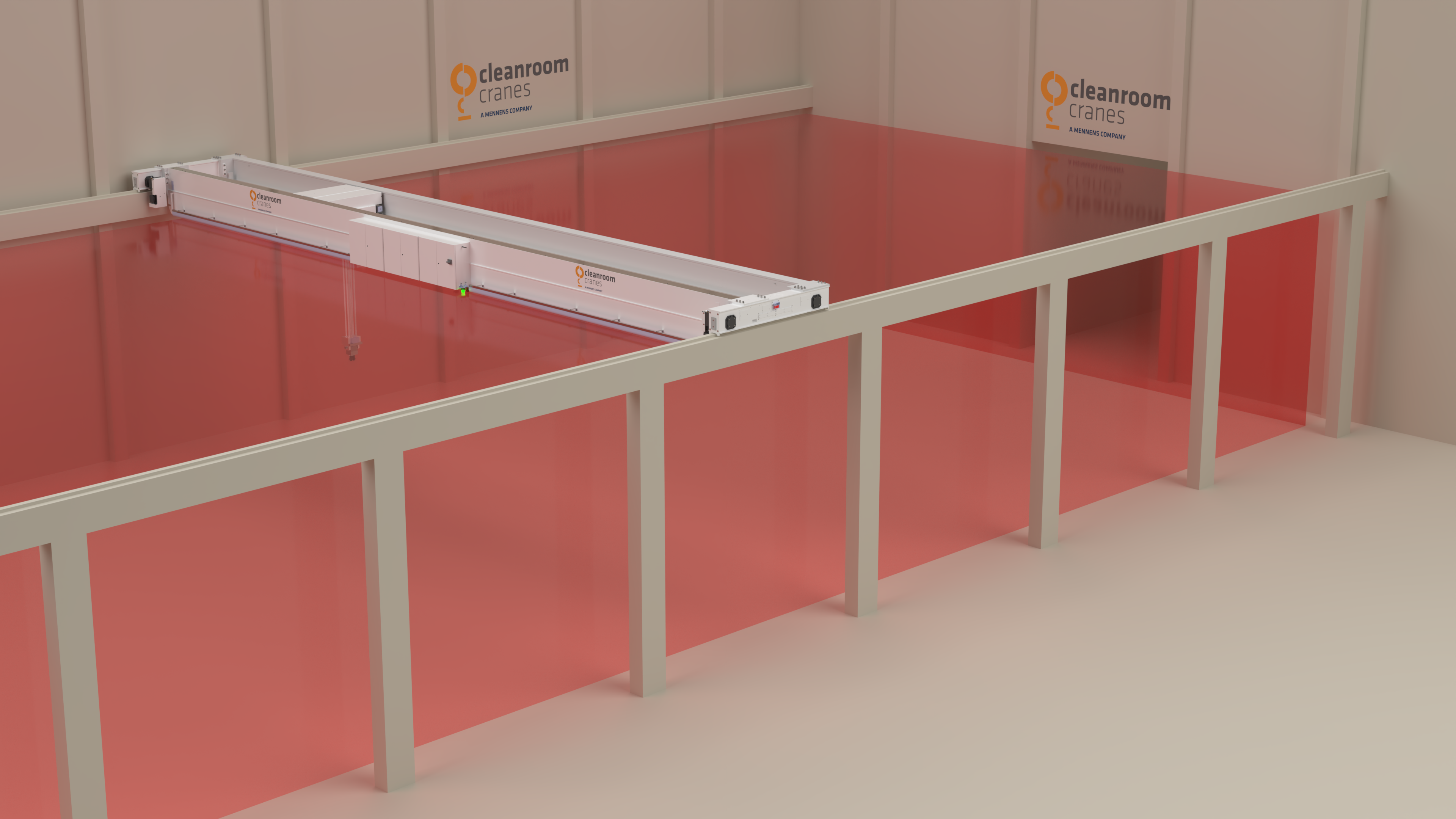

At Cleanroom Cranes (part of Mennens), we design our cranes to perform according to the requirements of the cleanroom and its associated ISO standards. However, there is no fixed set of parameters for this. Numerous factors come into play, such as the industry and the product being lifted, the speed at which the load needs to be moved, and the direction of movement. Additionally, the number of people performing tasks within the cleanroom is also a consideration.

There are many sources that emit particles. The total emission is the combined result of all these "polluters." The aim of all cleanroom parties involved is to prevent these emissions as much as possible. However, it is not always possible to eliminate all contamination. That is why cleanrooms are equipped with comprehensive air filtration systems. The principle is simple: what is not emitted does not need to be filtered out.

The ISO 14644 standard and its associated classifications apply to cleanrooms in general, across various industries where they are used. In addition to this standard, there are also industry-specific and/or process-specific requirements. For example, factors of importance in the food industry may differ from those in the semiconductor industry. Moreover, the conditions within sector-specific cleanrooms can vary significantly.

It is therefore not the case that we offer a single lifting solution per ISO classification and sector. However, we do have a standardized design that serves as a starting point. We configure this design based on the requirements and characteristics of the cleanroom. This is an advantage for our customers, as it eliminates the need to develop the crane from scratch each time. This saves development time and costs.

Testing through a zero measurement

How do we determine if the crane fits within a specific classification? And what adjustments may be necessary? We discover this through extensive testing. We start with a zero measurement. We test how the crane performs when stationary. Subsequently, we measure factors such as the particle count when the crane is loaded, moving up and down, moving from front to back, and coming to a stop. The exact measurements we conduct depend on the conditions within the cleanroom.

Simulating operational conditions

We simulate the operational conditions within the cleanroom to discover what effect the addition of the lifting equipment has on the level of particles present. During one of our initial tests, we discovered the polluting effects of human presence. While conducting an ISO test on a crane, a staff member accidentally entered the testing area, and the particle count graph immediately spiked. Humans remain one of the largest sources of emissions in the cleanroom.

Adjustment and validation

The tests yield various specific values. These allow us to determine in which situations the crane meets specific standards. If necessary, we make adjustments to the crane. Once the crane is delivered, we have it validated by our customers. Their feedback is invaluable as it enables us to continuously improve our cranes based on practical experiences. This ensures that you can rely on an optimally performing cleanroom crane that operates within the specified ISO value.

Curious about the possibilities? Contact us!

Are you curious about the possibilities and added value of a crane for your cleanroom? Or would you like to exchange ideas without any obligation? Feel free to contact us.

.jpg?width=414&height=414&name=Contact%20image%20414x414%20(1).jpg)