"To achieve the cleanest possible lifting solution with a cleanroom crane, every detail has to be just right"

Cranes (13)

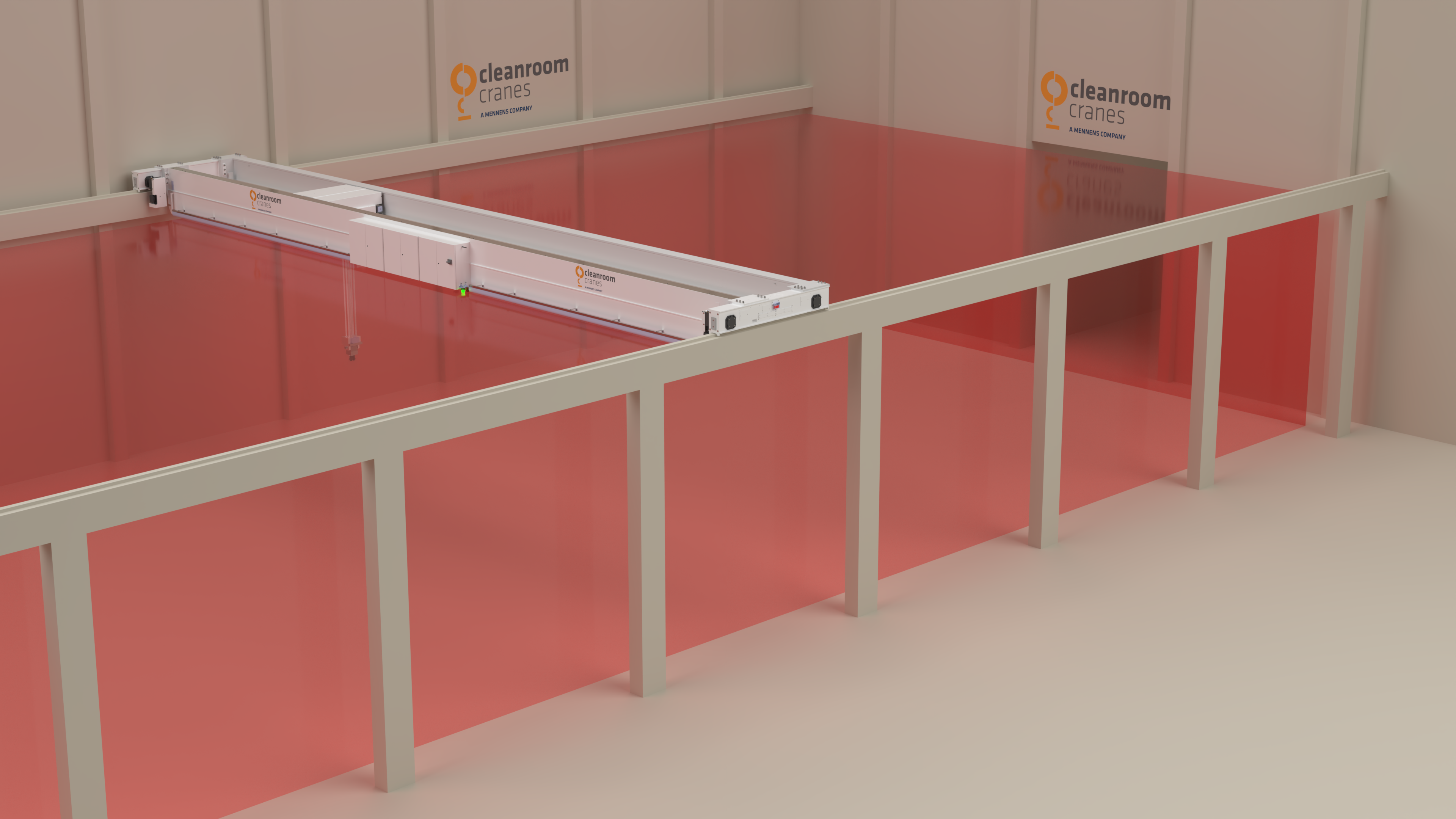

Using a lifting crane in a cleanroom or controlled environment offers massive benefits in terms of efficiency. But air purity, particle dispersion and outgassing levels do have to be kept in check. What does this involve?

Theun Kemps has more than 20 years of experience in contamination control, such as in cleanrooms and controlled environments. As an independent expert, he advises organisations on this subject. In his role, he also handles the validation process for the cleanroom cranes from Mennens Cleanroom Cranes.

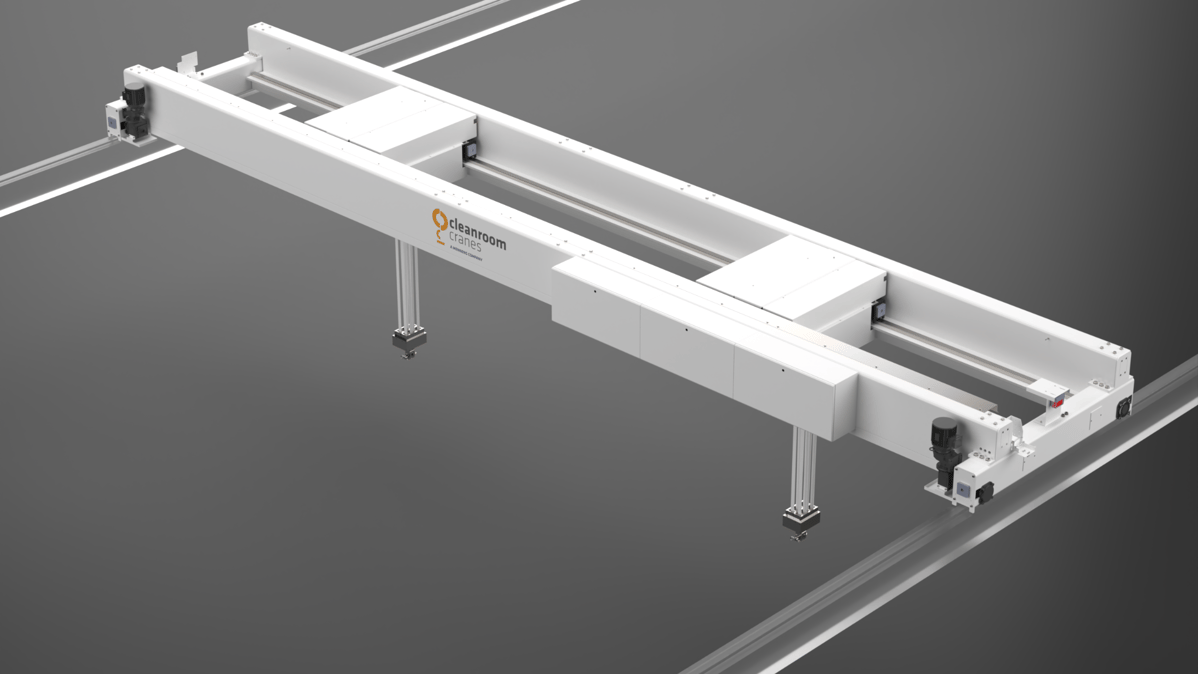

Special design

Theun begins: “During the conversations I have with organisations about setting up their cleanrooms or controlled environments, lifting solutions tend to come up fairly quickly. For example, for a very precise assembly or moving of heavy expensive semiconductor manufacturing equipment. Or for creating an extremely clean daily process in paint departments in the automotive industry.”

Preventing particle dispersion

These organisations have to deal with strict standards regarding the maximum amount of particles or other contaminants allowed on their products. How can that be compatible with a lifting device? Theun: “Most facilities in a cleanroom are static in nature. This does not apply to lifting cranes, which are dynamic. That causes particle movement, which is something you actually want to limit. This is because the particles could end up on or in your product, which is not a desirable situation. To minimise contamination during the lifting process, cleanroom cranes require a special design and use of materials that differs from conventional lifting cranes. A cleanroom crane needs to be completely geared towards the process, the applicable ISO classification and industry-specific requirements.”

Choice of material

How can contamination be minimised during the lifting process? Theun: “For example, by using materials to manufacture the lifting crane that are non-contaminating or that have minimal contamination and that are permitted inside the cleanroom. For instance, one major player in the semiconductor industry has banned the dynamic use of copper. When copper particles enter a semiconductor machine, they can migrate through the system. This can lead to disruptions at the wafer level, meaning failure of microchips and ultimately production losses. Elements such as tin and zinc are also banned in this case, which are examples of HIO (Hydrogen Induced Outgassing) elements. These elements can lead to transmission loss of the optical column, which in turn can cause major irreversible damage.”

Stainless steel: easy to clean and corrosion resistant

Many of the cleanroom lifting cranes from Mennens Cleanroom Cranes are made of stainless steel. Theun: “Stainless steel is more expensive than steel, but it is strong and has very high resistance to corrosion. This material is also easy to clean. And it leaves little to no particles behind.”

Lifting sling and winding methods

Every last detail is considered when engineering cleanroom lifting cranes to prevent contamination. Theun: “Let’s take the lifting equipment (the sling, rope or cable) you are using to hoist, and the method of winding. The Dyneema lifting sling has been developed for many cleanrooms in sectors such as the semiconductor, high-tech and aerospace industries. Dyneema is strong, flexible and has a low coefficient of friction. As a result, the sling barely has any wear and only disperses a minimum number of particles. For the space, aerospace and semiconductor industries, the outgassing of materials is also very important here. Dyneema is also low stretch and lightweight.”

There is a wide range of innovative design options that minimise the contamination caused by cranes. Theun: “This includes custom-developed powder coatings and only having smooth surfaces. In other words, no cracks, no openings and no hollow spaces where dirt can accumulate and bacteria can develop. And materials within the permissible outgassing level.”

ISO 14644-1 2015 and industry-specific requirements

Of course, the design required for cleanroom lifting cranes varies by industry, organisation and environment. Theun explains: “This has everything to do with the particles allowed under the ISO 14644-1 2015 and industry-specific requirements. In cleanrooms for the space/aviation industry, relatively large particles are usually allowed on surfaces, e.g. 100 microns. This falls under particle dispersion. Compare that to the semiconductor industry, for example, where wafer-level particles as small as 4 nanometres (nm) can cause defects. The cleanroom crane, of course, is inside the cabin, outside the machine. But it obviously also has its impact on the design requirements.”

Electromagnetic compatibility

One concern in cleanrooms – apart from contamination – is the electromagnetic compatibility (EMC) of the electrical components in the crane. Theun: “To ensure that the components in the crane do not interfere with the components or equipment in the cleanroom, they are completely shielded with special materials in the design. Cables in the crane are encapsulated in the steel parts of the frame using glands to achieve complete shielding.”

Validation

As an organisation, you want to ensure that the lifting crane is cleanroom compatible and that it performs within the applicable ISO classification. And there might also be product requirements within the particular industry. How can you make that verifiable?

Validating cleanroom equipment such as cleanroom lifting cranes is a regular part of Theun's work as an independent expert. He explains the process:

“Validation takes place in a cleanroom or conditioned environment. It involves using a laser particle counter, for example. This is sophisticated equipment used to determine the number of particles in the air. The laser particle counter draws in air to measure how much the crane emits. A zero measurement is taken first to establish the context. The next step is to measure how many particles are released during the different operating stages of the crane.

All of this data is visualised in a report. And what if the crane doesn’t perform within the ISO classification requirements, for example? Then the cleanroom crane goes back to the engineering process. However long it takes for the crane to be completely cleanroom compatible. And for it to perform within the relevant ISO standards or other applicable classification.”

Theun Kemps - Contamination Control Engineering

www.contaminationcontrolengineering.com

info@theunkemps.com

.jpg?width=414&height=414&name=Contact%20image%20414x414%20(1).jpg)