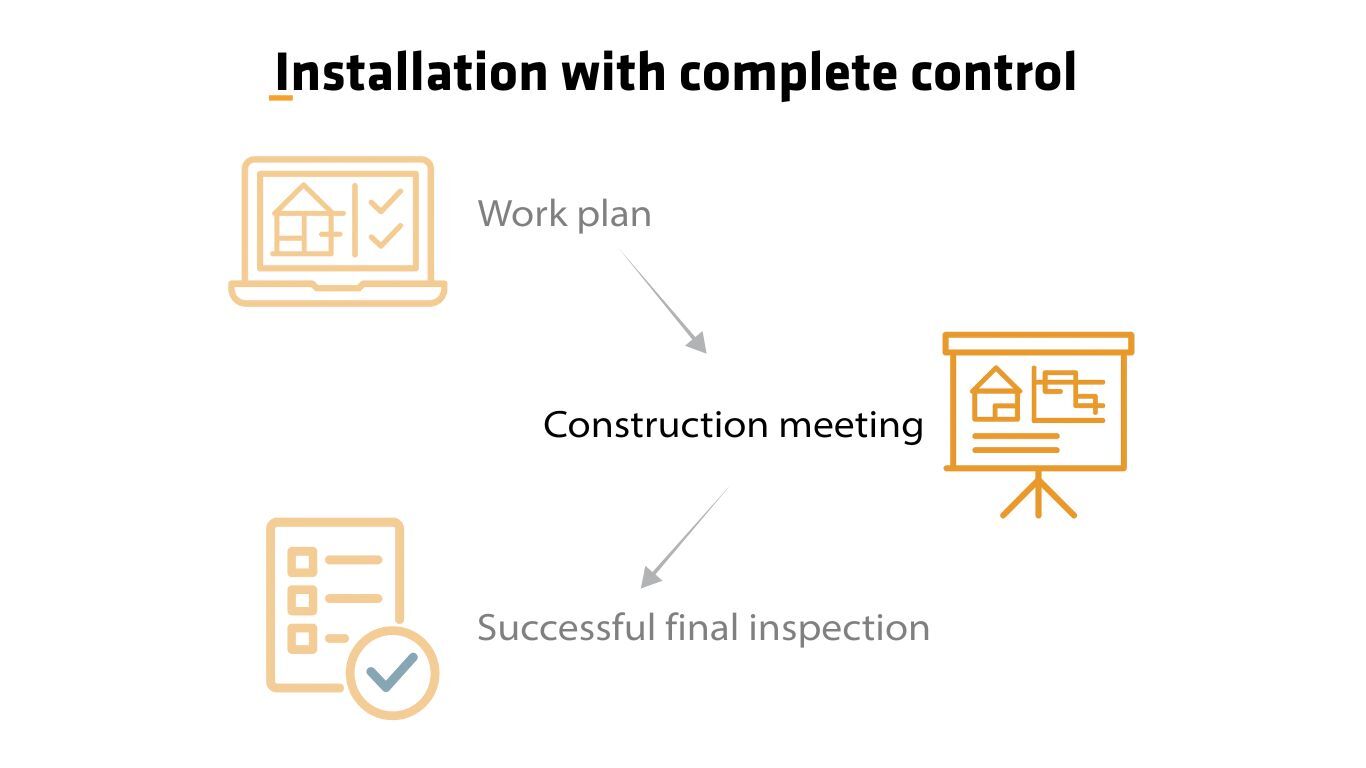

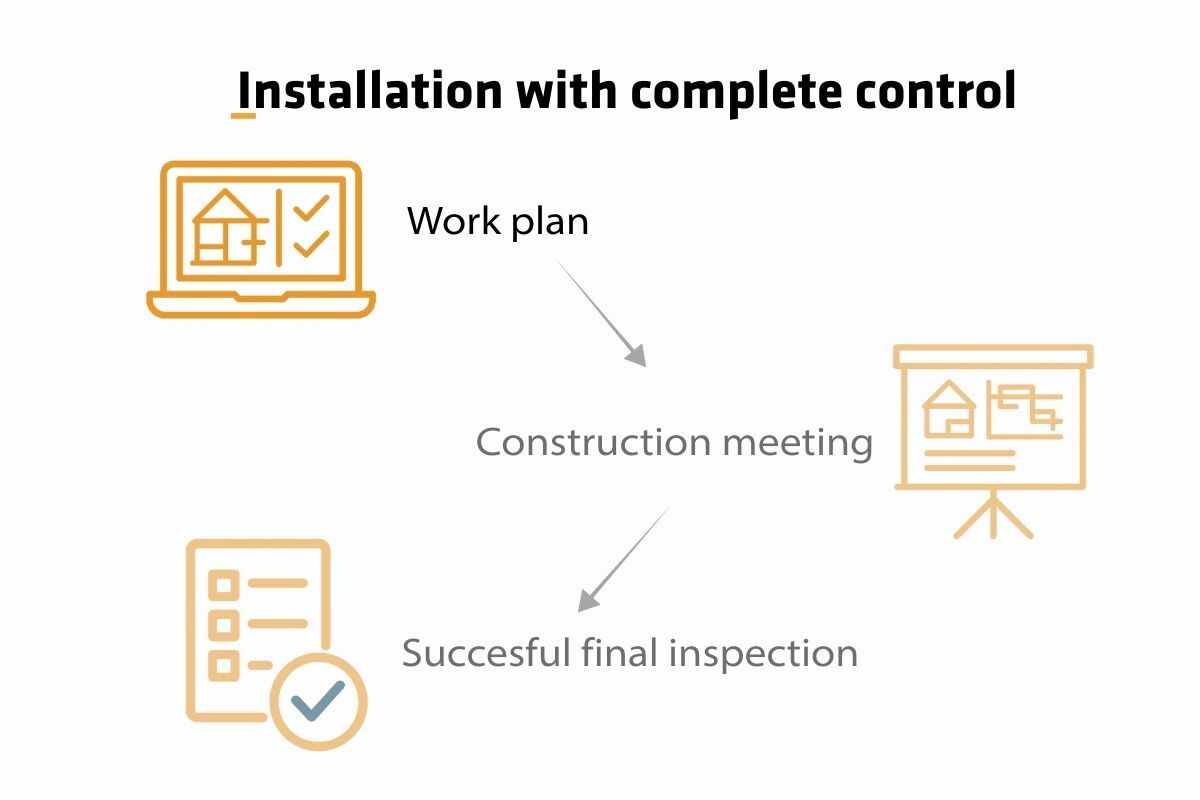

How we install your cleanroom crane: no surprises, full control

Installation (3)

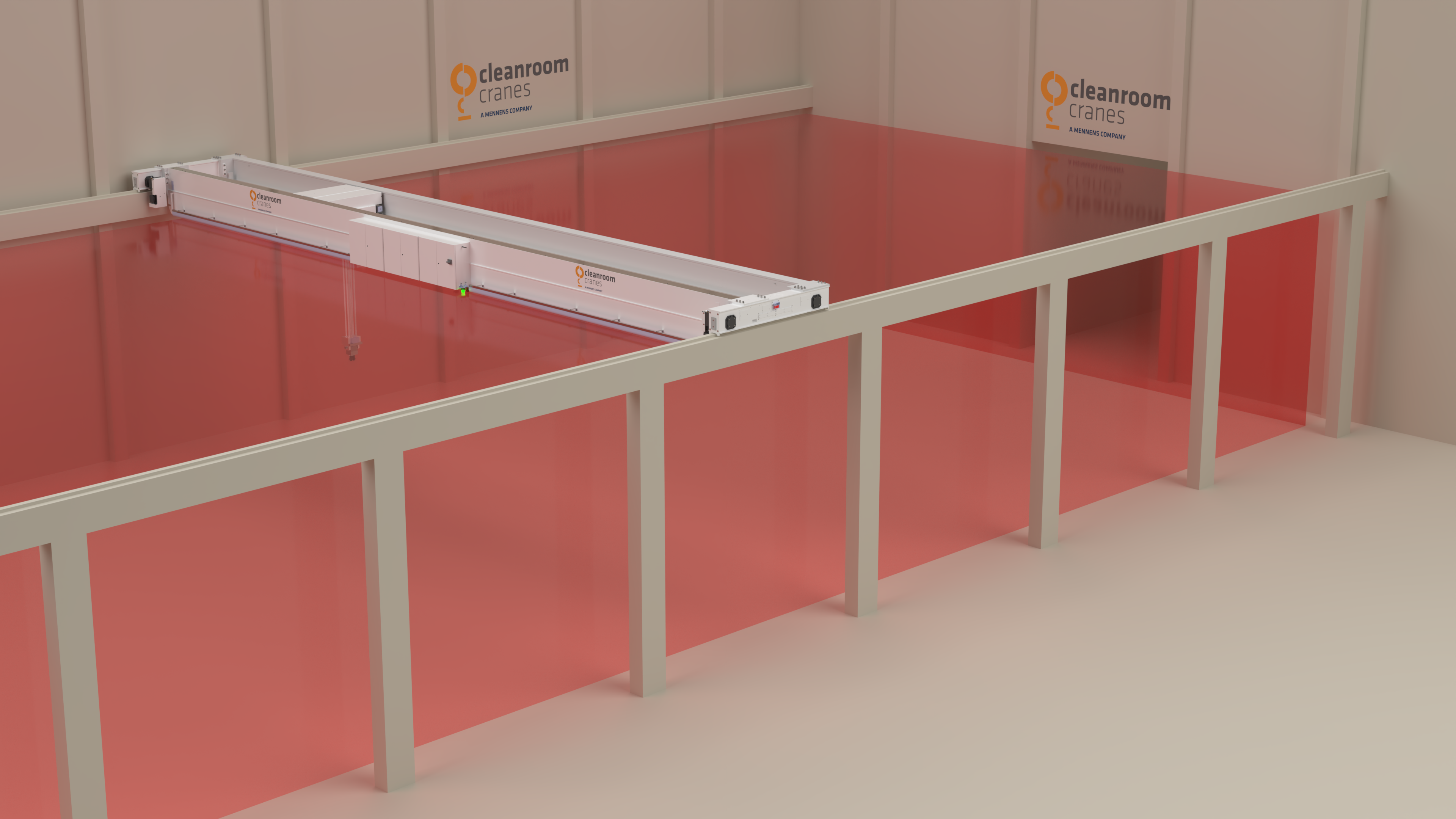

When building a cleanroom, every detail matters. Air quality, the choice of materials, the positioning of equipment: everything must align. At first sight, a crane may seem like just another component, but in practice it is a crucial link in the overall process. At Mennens Cleanroom Cranes we understand this better than anyone. No lifting solution is ever standard. Each crane is designed and installed with close attention to the unique requirements of the customer.

.jpg?width=414&height=414&name=Contact%20image%20414x414%20(1).jpg)