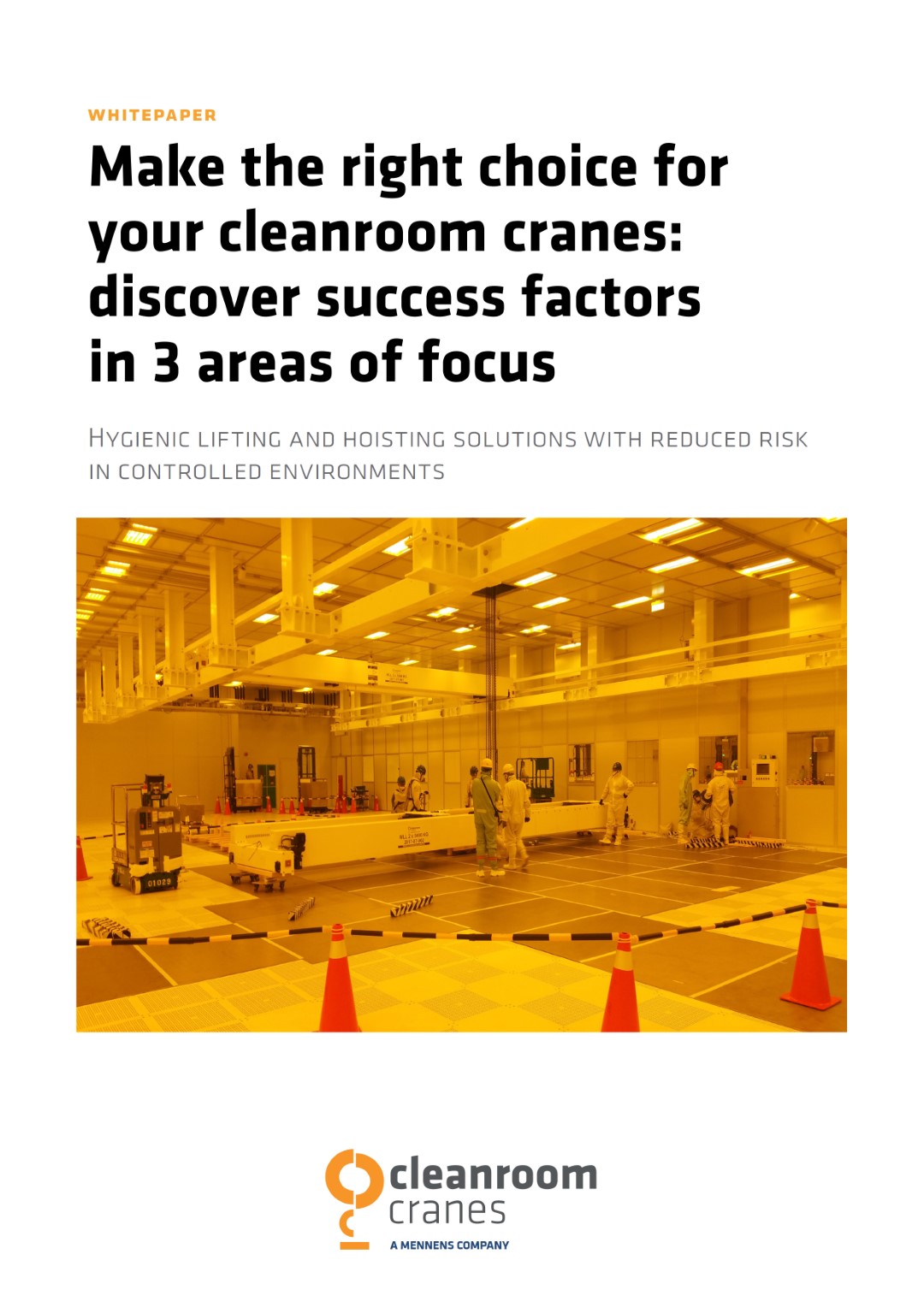

Overhead cranes

Maximum lifting range, without any loss of workspace.

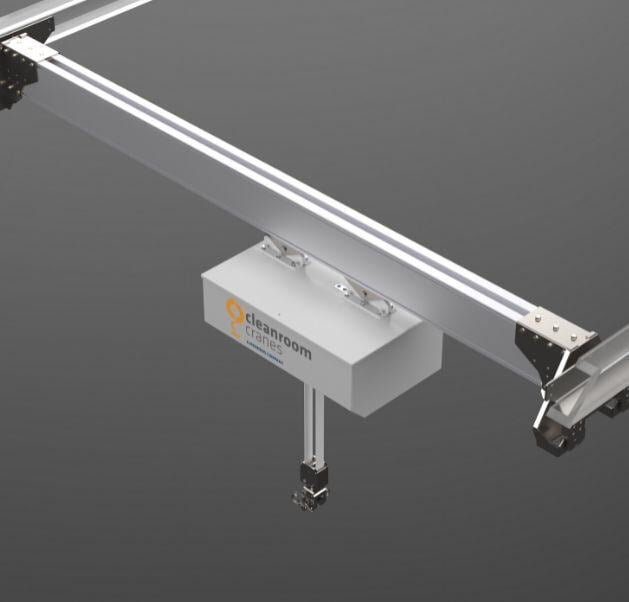

With an overhead crane, you can count on a maximum lifting range. Thanks to the elevated runway, the floor area remains free. Our overhead cranes come in lightweight aluminium constructions as well as heavier steel versions. With spans ranging from 2 to 30 metres, you can move any load to any position efficiently and with millimetre accuracy. Without any physical effort and with reduced contamination.

We offer different overhead cranes

.jpg?width=629&height=602&name=Bovenloopkranen%20Main%20image%20%20(EXE%20LHD%2023).jpg)

Double girder overhead crane 2 x 10 ton

.jpg?width=629&height=602&name=Bovenloopkranen%20sub%20image%20-%20Double%20girder%20overhead%20crane%20detail%20(EXE%20LHD%2019).jpg)

Hook block 10 ton hoist

.jpg?width=629&height=602&name=Bovenloopkranen%20sub%20image%20-%20Normal%20double%20girder%20overhead%20crane%20(Lasertec%2010).jpg)

Double girder overhead crane 1 ton

.jpg?width=629&height=602&name=Bovenloopkranen%20sub%20image%20-%20Lightweight%20overhead%20crane%20(Blondin%203).jpg)

Lightweight overhead crane type Blondin 5 ton

.jpg?width=629&height=602&name=Bovenloopkranen%20sub%20image%20-%20Lightweight%20overhead%20crane%20detail%20(Blondin%206).jpg)

Lightweight overhead crane type Blondin detail

.jpg?width=629&height=602&name=Single%20girder%20overhead%20crane%201%20(1).jpg)

Single girder overhead crane 500 kg

.jpg?width=629&height=602&name=Single%20girder%20overhead%20crane%202%20(1).jpg)

Single girder overhead crane 2 ton

Single girder overhead crane 1 ton

Your benefits

Our overhead cranes for cleanrooms allow you to move loads efficiently and accurately, both horizontally and vertically.

Space-saving

Thanks to its overhead construction, the crane has a low-volume design.

Maximum reach

Overhead cranes cover the entire area of your space.

Extremely precise

With precision control, you can lift highly sensitive loads with millimetre precision.

Safe and clean

The cranes prevent contamination to the greatest degree possible. Easy to clean.

ISO compliant

Your overhead crane complies with the applicable standards and ISO classifications.

Minimum dispersion

Designed and tested for minimum particle dispersion.

Space-saving

Thanks to its overhead construction, the crane has a low-volume design.

Maximum reach

Overhead cranes cover the entire area of your space.

Extremely precise

With precision control, you can lift highly sensitive loads with millimetre precision.

Safe and clean

The cranes prevent contamination to the greatest degree possible. Easy to clean.

ISO compliant

Your overhead crane complies with the applicable standards and ISO classifications.

Minimum dispersion

Designed and tested for minimum particle dispersion.

Industries

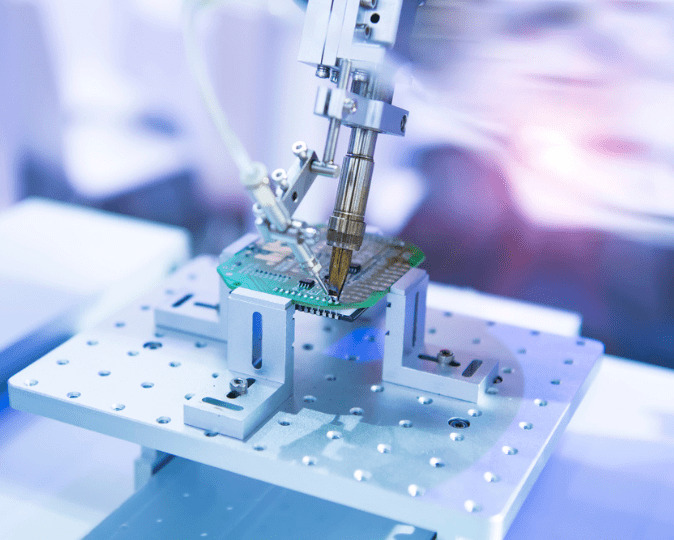

- Semiconductor industry

- Hightech

- Food industry

- Biotechnology

- Battery industry

- Aerospace

- Aviation

- Semiconductor industry

-

Semiconductor industry

Need to move heavy semiconductor manufacturing equipment accurately, safely and efficiently? Or position light components in exactly the right place?

With over 25 years of experience in the semiconductor industry, you can count on lifting equipment that meets all the requirements. And keep particulate emissions to an absolute minimum in the process.

Hightech

Does your company supply components or parts with ‘cleanliness grade' 4 or 2? We design your lifting equipment so that your production process meets the often highly demanding requirements and specifications set by your partner(s).

At the same time, a cleanroom crane speeds up your process, helping you create greater efficiency and achieve higher profitability.

Food industry

As a player in the food industry, you know full well: everything hinges on food safety. With our hygienic cleanroom cranes, you minimise the risk of potential microorganism formation and contamination.

Our cranes help you comply with laws and regulations, including sector-specific hygiene codes such as those set by the NVWA.

Biotechnology

Pharmaceutical and medical biotechnology processes demand the lowest possible levels of contamination. Preventing contamination is a priority. Process reliability and product safety are also equally important.

Our cleanroom cranes contribute to a safe and traceable process flow with parameters that can be adjusted in detail. They cause minimal to no contamination and prevent the risk of microorganism formation.

Battery industry

Cleanliness and safety are crucial in battery manufacturing. A cleanroom crane allows you to streamline your production process while ensuring that contamination dispersion is kept to a minimum.

Design choices can minimise the dispersion of particles such as dust and trapped contamination. With the right choice of materials, it is also possible to make your lifting equipment explosion-proof.

Aerospace

You need to be able to position or move aerospace objects carefully and appropriately. A non-contaminating and precise crane will help ease your R&D or production process.

Our lifting solutions are safe for use in developing the most sensitive parts, such as satellite components, robotic arms or sun shields.

Aviation

Lift critical aviation parts and components with extreme precision and minimal contamination. Ensuring that every single detail is correct.

Our cleanroom cranes are precise and leave no dust, liquid or paint particles behind. Therefore, cranes contribute significantly to reliability in terms of instruments and engines, etc.

The expertise of Cleanroom Cranes

Engineering

More than 25 years of experience

Customized solutions

Cranes that fit seamlessly into your working environment

Testing

For a flawless and smooth operation of your cleanroom crane

Training

Your employees learn to safely operate the crane

Service

Our experts offer 24/7 service worldwide

The European Space Agency (ESA) lifts cleanly and accurately

"Dyneema rope is made of a very strong fiber and emits practically no particles."

Jarno Vermunt

Manager Projects

For a new ISO 5-cleanroom ESA called in the expertise of Mennens Cleanroom Cranes. Based on ESA’s requests and specifications a tailor-made lifting solution was designed.

With a 16 tons cleanroom crane with a dust extraction system any conceivable form of contamination is prevented.

Frequently Asked Questions

.jpg?width=674&height=568&name=FAQ%20674%20x%20568%20(1).jpg)

Why choose an overhead crane?

An overhead crane ensures optimal space utilization by being suspended at the top of the production room or cleanroom. This maximizes available floor space, providing a large lifting range and maximum flexibility in the factory.

Advanced controls offer extreme precision, essential for delicate and complex lifting activities. With simple controls explained to employees during installation, the crane can be quickly and smoothly put into operation.

Why do I need a special crane for a cleanroom when I want an overhead crane?

Cleanroom cranes prevent contamination, essential for a clean and safe working environment. These custom-made cranes are ideal for delicate production and assembly processes, precise controls for optimal control and safety during lifting activities.

They are specifically designed not to contaminate your environment, reducing the time and cost needed to keep the crane clean and minimally burdening the air purification system.

What is the difference between a single girder and a double girder crane?

A double girder crane offers more lifting height and power because the hoist is positioned between the girders.

A single girder crane is ideal for simplicity and cost-efficiency, with the hoist positioned under the girder.

Both provide reliable lifting solutions. The choice depends on your specific needs and situation, as each location is unique. Therefore, the best option is determined per situation.

How many kg can an overhead crane move?

The capacity of an overhead crane determined by the customers specification. The crane is designed accordingly, so almost any desired load limit can be met.

Our cranes can handle both light lifting activities and heavy applications, with a maximum lifting capacity of 40 tons. They provide the strength and reliability for the most demanding lifting activities.

How does the process of installing a crane in the factory proceed?

The process begins with an informative meeting to discuss your needs and requirements.

Then follows the design process, production, testing of the crane, and transport. Upon arrival, the crane is smoothly installed.

After installation, you receive instructions and maintenance information. Our technicians are ready worldwide for quick problem-solving.

Can't find your question? Contact us using the form below or send us an email.

.jpg?width=674&height=568&name=FAQ%20674%20x%20568%20(1).jpg)

Need customization?

Our experts will get to work for you.

1. Contact with an expert

We want to get to know you, so that we can advise you based on your situation and needs.

2. Detailed quotation

You will receive a detailed quotation with drawings.

3. Production & Testing

We design, produce and test your cleanroom crane thoroughly.

4. Delivery & Installation

Our professionals deliver and install the crane on-site and carry out a final test.

5. Service

Extend the lifespan of your cleanroom crane with a tailor-made maintenance program.

-

1. Contact with an expert

We want to get to know you, so that we can advise you based on your situation and needs.

-

2. Detailed quotation

You will receive a detailed quotation with drawings.

-

3. Production & Testing

We design, produce and test your cleanroom crane thoroughly.

-

4. Delivery & Installation

Our professionals deliver and install the crane on-site and carry out a final test.

-

5. Service

Extend the lifespan of your cleanroom crane with a tailor-made maintenance program.

Mennens Cleanroom Cranes B.V.

Achtseweg Zuid 161

5651 GW Eindhoven

The Netherlands

T +31(0)88 425 83 00

sales@cleanroomcranes.nl www.cleanroomcranes.nl

Need customization?